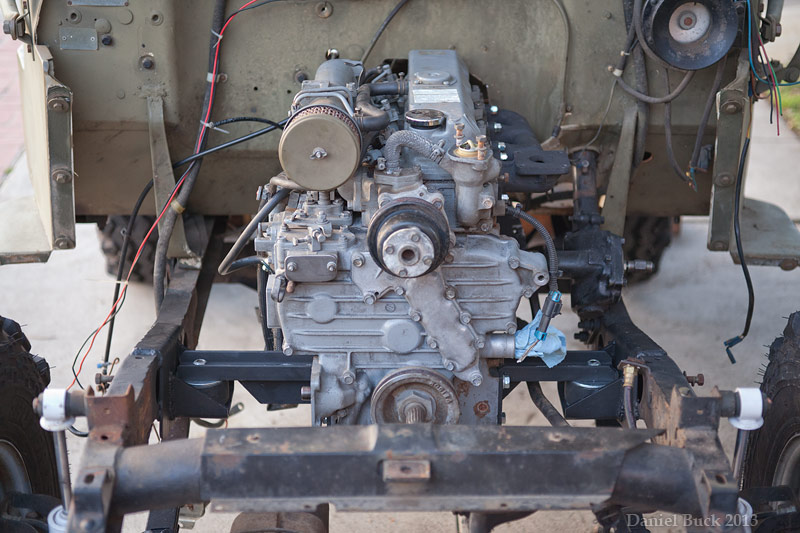

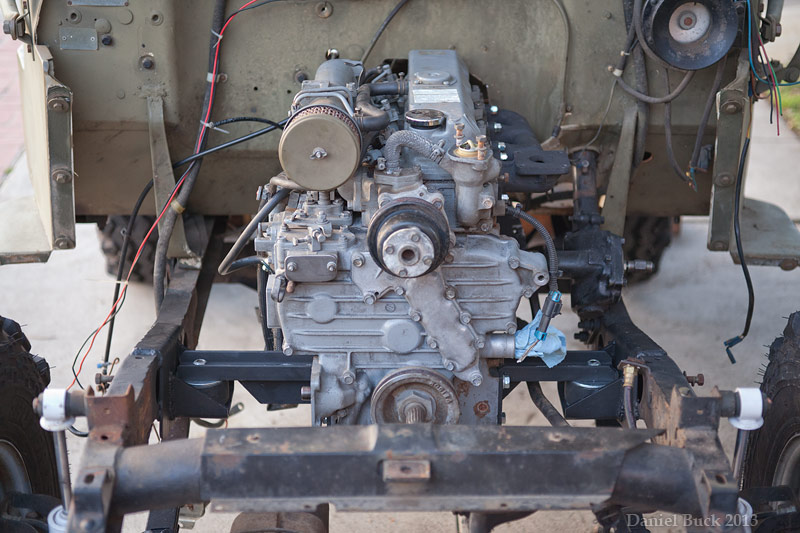

motor mounts are done

I'm not thrilled at how well the welds turned out, I seem to do ok when it's horizontal and I have room to work, but for the vertical and upside down welds where I was cramped and contorted just to see what I was doing, I'm not to happy with those. I did run the welds with 3 passes. Probably overkill, but I figure since I wasn't comfortable with the welds, and it's only 110 power, it probably doesn't hurt to have them multi-passed. Just nobody look on the underside of my motor mounts!!

I'm not thrilled at how well the welds turned out, I seem to do ok when it's horizontal and I have room to work, but for the vertical and upside down welds where I was cramped and contorted just to see what I was doing, I'm not to happy with those. I did run the welds with 3 passes. Probably overkill, but I figure since I wasn't comfortable with the welds, and it's only 110 power, it probably doesn't hurt to have them multi-passed. Just nobody look on the underside of my motor mounts!!

Comment