I'd sure hope it would be good after only a year. My radiator had a minor leak at the top plastic tank. I don't like plastic tanks and I didn't want to screw with it, so I just bought a 3-row brass "desert cooler" rad.

Announcement

Collapse

No announcement yet.

turbo diesel Willys!

Collapse

Forum Thread First Post

Collapse

X

-

Thanks for that tip! :-) I don't know a whole lot about brakes (learning every time I touch the jeep, haha!) Would those cylinders work for disc brakes? I'm thinking about putting some disc brakes on the front[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

Discs use a caliper that squeezes the rotor, drums push the shoes outward from the top and use an adjuster at the bottom to try to keep the wear on the shoes even. It may be worth it though to look into putting those on the rear drums. What size are your current rear drums?God forgives, rocks don't

-sons of thunder

Comment

-

I'm not sure. Probably 9"?[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

Got the engine out!! It was actually pretty easy, I was expecting it to be difficult, but it went pretty smoothly. Might be a little easier if it wasn't all covered with oil :laughing:

Now I wonder what parts of the clutch I can re-use?

(my buddy Chris, who stopped by to help out)

[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

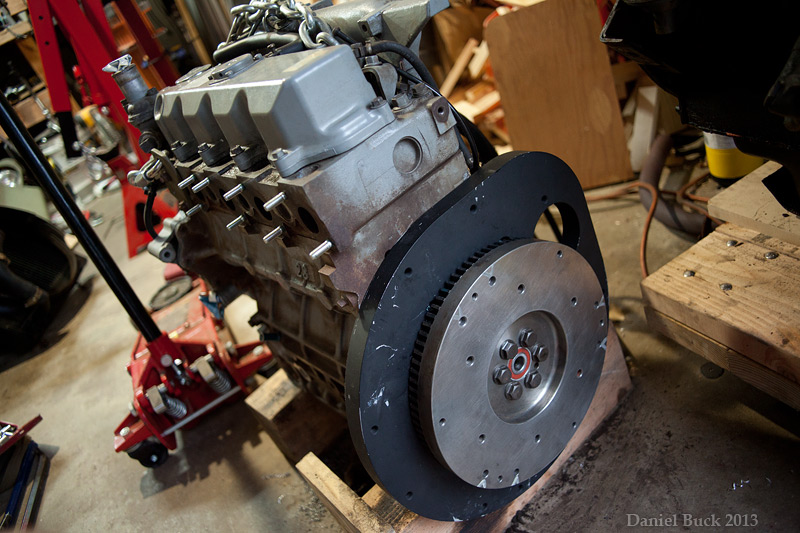

slowly making progress. Got the adapter plate, flywheel, and starter bolted on. (took the photo before I bolted on the starter)

[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

yea, about that. Aluminum [COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

started making the adapter plate for the turbo. The exhaust manifold bolt holes are farther apart than the bolt holes on the turbo exhaust inlet. So... I picked up a HUGE washer from McMaster-Carr (a shopping mall for men! haha :smokin: ) which gives me a head start with the large hole already drilled in the center. My drill press is old and tired, it's chuck is wobbly, and it spins way to fast for metal even on the slowest belt setting. But I make it work, for now. It was my father's, it was good enough for him, it's good enough for me

These are the counter sunk holes for the allen head bolts that will mount the adapter to the exhaust manifold. Once I get the engine into the engine bay, I'll place the turbo on top and figure out where i need to drill the holes to mount the turbo. I'll drill those holes, tap them, and insert studs. There's not enough room underneath to have a bolt head or a nut, so they will have to be studs. It makes sense in my head, I think it will work! The washer is 4" OD, 1.25" ID, and 1/2" thick, about $7 from McMaster if I remember correctly.

I'll still need to file out the hole a bit larger to fit the turbo exhaust inlet size, but at least the center hole gives me a head start, I don't have a bit near large enough to drill a hole that size in steel.

Last edited by daniel_buck; 05-22-13, 08:37 PM.[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

Last edited by daniel_buck; 05-22-13, 08:37 PM.[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

McMaster-Carr is pretty dang cool. Looks like you're off to a good start.

If I wanted to cut a large hole using a drill press (as opposed to a mill), I would probably use a large hole saw--done it many times, in fact.

Both of my little HF drill presses I got from my Dad, and they have been indispensable for me. One day I may shim the quills though holes = cowbell

holes = cowbell

Comment

-

Looking good!

I don't know if you've seen this, or if it will fit your drill, but it may be worth it if you plan to do a lot more metal work with that drill press. They have threads on Pirate and JF with more pictures.

https://www.roguefab.com/product.php?id=35"The Jeep...is a fitting instrument to transport the free people of a free nation with the respect to which we are entitled and the dignity that we deserve."

Comment

-

Yea, I've seen that. Would be great to slow the bit down! But I figured with the wobbly chuck (or whatever it is that's wobbling) probably not worth putting money into. Unless I could fix the wobble. I don't know if there are replacement parts for my drill press available or not, I'll have to look into that.[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

Well the disc brakes that I was going to put on the front don't fit with my wheels (I knew it was kind of a gamble) so, I'm going to leave the factory size drums up front for now, and just put in the dual master cylinder. I can put on 11" drums later on once I get the jeep on the road again. The brakes were fine for in-town, I'll just be sure and do something about them before I hit the mountain roads again.

I don't think it'll be any more difficult to change out the brakes with the engine in and fenders on, than it is now. So I'll put that off to later, and focus on getting the rest of the jeep done :-)

I took out the fuel tank and fuel line, and removed the old master cylinder, and started drilling and getting the new dual MC mocked up.

The old engine was picked up by a nice fella from the cj2a forums, I have a bit more space in the garage now, and some cash [COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

Comment