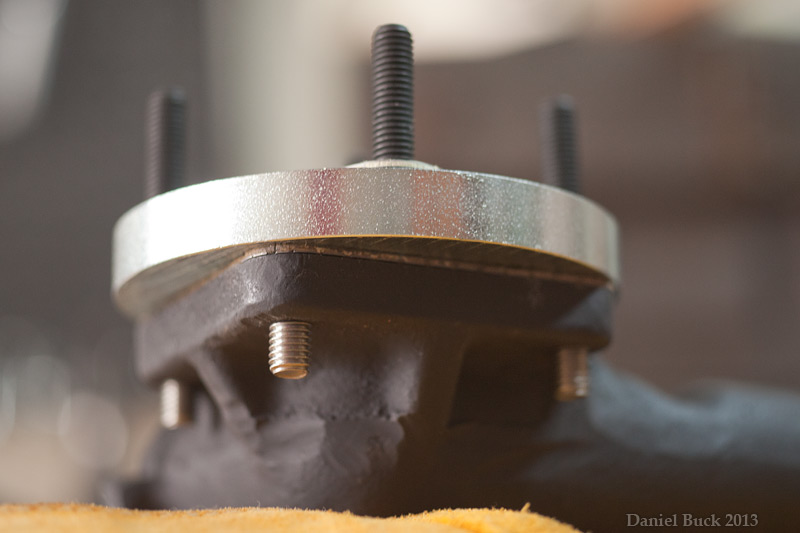

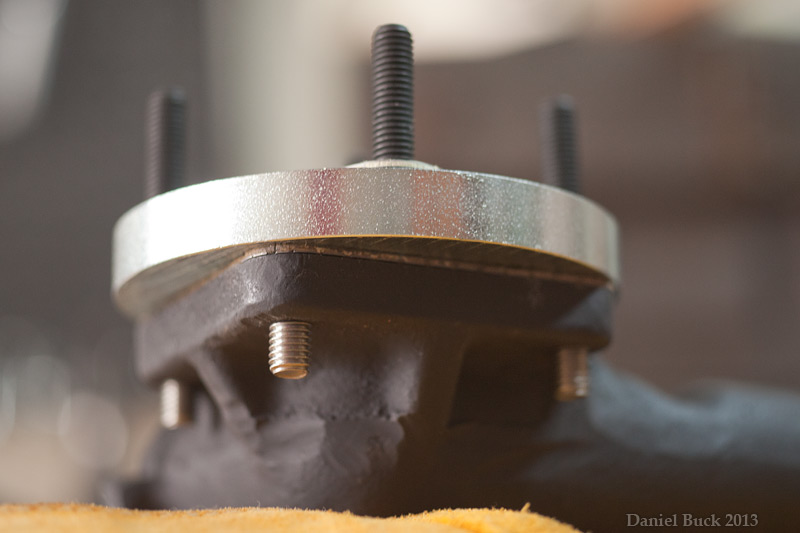

Here's how it will go. I'm just balancing the studs on top of the plate right now, I'll drill and tap the holes for the studs once I have the engine in, and know the orientation of the turbo that I want.

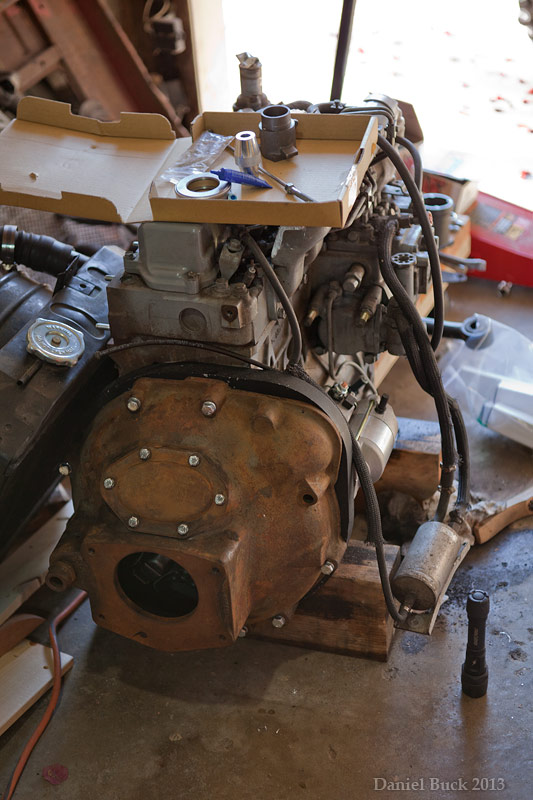

I'm still going to port out the exhaust manifold and adapter to be the same diameter as the turbo, it needs to be a bit larger.

I'm still going to port out the exhaust manifold and adapter to be the same diameter as the turbo, it needs to be a bit larger.

Comment