Announcement

Collapse

No announcement yet.

Nick's CJ build part 1

Collapse

Forum Thread First Post

Collapse

X

-

Originally posted by dirtman13 View PostSince it will be your triumphant return I was thinking something more like this.

[ATTACH=CONFIG]1360[/ATTACH] [CENTER][COLOR=#ff0000]Resistance Off Road

[CENTER][COLOR=#ff0000]Resistance Off Road

[/COLOR]Join the Resistance...

http://www.resistanceoffroad.us[/CENTER]

Comment

-

We are starting make real progress on the CJ. I hope we can keep up the momentum. Got some more roll cage work done including the seat mounts, window cross bar, several straight pieces, lowered the radiator support several inches, repaired a bad sheet metal job on the DS rear wheel well, got a start on the high line front fenders and more.

Billet Brake line/fuel line clamps

20140925_135829 by MJR RAT, on Flickr

20140925_135829 by MJR RAT, on Flickr

20140925_135927 by MJR RAT, on Flickr

20140925_135927 by MJR RAT, on Flickr

New seats.

20140925_100003 by MJR RAT, on Flickr

20140925_100003 by MJR RAT, on Flickr

Seat frames. Because the seats are so high (made for little tuner cars) the frames had to sit low in the tub. The original mounting height was good for the old YJ seat, but these, not so much...

20140925_144833 by MJR RAT, on Flickr

20140925_144833 by MJR RAT, on Flickr

20140925_172559 by MJR RAT, on Flickr

20140925_172559 by MJR RAT, on Flickr

Umm yeah. Nose bleed seats

20140926_101640 by MJR RAT, on Flickr

20140926_101640 by MJR RAT, on Flickr

So cut the old...

20140926_140658 by MJR RAT, on Flickr

20140926_140658 by MJR RAT, on Flickr

Make the new

20140926_151811 by MJR RAT, on Flickr

20140926_151811 by MJR RAT, on Flickr

20140928_130759 by MJR RAT, on Flickr

20140928_130759 by MJR RAT, on Flickr

20140928_152817 by MJR RAT, on Flickr

20140928_152817 by MJR RAT, on Flickr

20140927_204121 by MJR RAT, on Flickr

20140927_204121 by MJR RAT, on Flickr

20140928_120457 by MJR RAT, on Flickr

20140928_120457 by MJR RAT, on Flickr

20140928_120516 by MJR RAT, on Flickr

20140928_120516 by MJR RAT, on Flickr

Mo betta

20140928_120531 by MJR RAT, on Flickr

[CENTER][COLOR=#ff0000]Resistance Off Road

20140928_120531 by MJR RAT, on Flickr

[CENTER][COLOR=#ff0000]Resistance Off Road

[/COLOR]Join the Resistance...

http://www.resistanceoffroad.us[/CENTER]

Comment

-

Starting the high line fenders and grinding out the sheet metal repair

20140928_130817 by MJR RAT, on Flickr

20140928_130817 by MJR RAT, on Flickr

Starting to look like a CJ again

20140928_152632 by MJR RAT, on Flickr

20140928_152632 by MJR RAT, on Flickr

Template for the inner fender plate. This will be 10 ga sheet metal and 1.25x.120 wall tube

20140926_111125 by MJR RAT, on Flickr

20140926_111125 by MJR RAT, on Flickr

Cuttin the hood. Yes!

20140926_111522 by MJR RAT, on Flickr

20140926_111522 by MJR RAT, on Flickr

Can I level with ya?

20140926_111837 by MJR RAT, on Flickr

20140926_111837 by MJR RAT, on Flickr

They recline too

20140926_183142 by MJR RAT, on Flickr

20140926_183142 by MJR RAT, on Flickr

Nick scavenged this green piece from his original tub. Thanks buddy, makes my life simpler.

20140928_200335 by MJR RAT, on Flickr

20140928_200335 by MJR RAT, on Flickr

20140928_200341 by MJR RAT, on Flickr

20140928_200341 by MJR RAT, on Flickr

20140928_200401 by MJR RAT, on Flickr

20140928_200401 by MJR RAT, on Flickr

I'll post some pics of the radiator mount and more fender work during the week.

Nite![CENTER][COLOR=#ff0000]Resistance Off Road

[/COLOR]Join the Resistance...

http://www.resistanceoffroad.us[/CENTER]

Comment

-

Starting on the fenders this week. Gonna be highlines. the main section will be 10 GA sheet metal. The rest will be tubing and 16 gauge. I think Nick wants the flares to be removable so that is in the works as well.

20140929_151012 by MJR RAT, on Flickr

20140929_151012 by MJR RAT, on Flickr

The sheet metal brake does NOT like 10 gauge. HAd to make a 4 foot lever bar for it.

20140929_151027 by MJR RAT, on Flickr

20140929_151027 by MJR RAT, on Flickr

20140929_151449 by MJR RAT, on Flickr

20140929_151449 by MJR RAT, on Flickr

20140929_151458 by MJR RAT, on Flickr

20140929_151458 by MJR RAT, on Flickr

20140929_151513 by MJR RAT, on Flickr

20140929_151513 by MJR RAT, on Flickr

More later.[CENTER][COLOR=#ff0000]Resistance Off Road

[/COLOR]Join the Resistance...

http://www.resistanceoffroad.us[/CENTER]

Comment

-

I like those seat mounts, low and going over the hump like that. That's kind of how I'm thinking of running the seat mount in my TJ. Thanks for taking photos of all that stuff, I've got good reference. Keep taking photos

At the top of the hump, it looks like you've spliced two tubes together. From what I read, for rollcage stuff putting a smaller diameter 'inner sleeve' in the splice points is common. What about something like this, for the seat mounts? Do you do bother using sleeves for the smaller tubing?

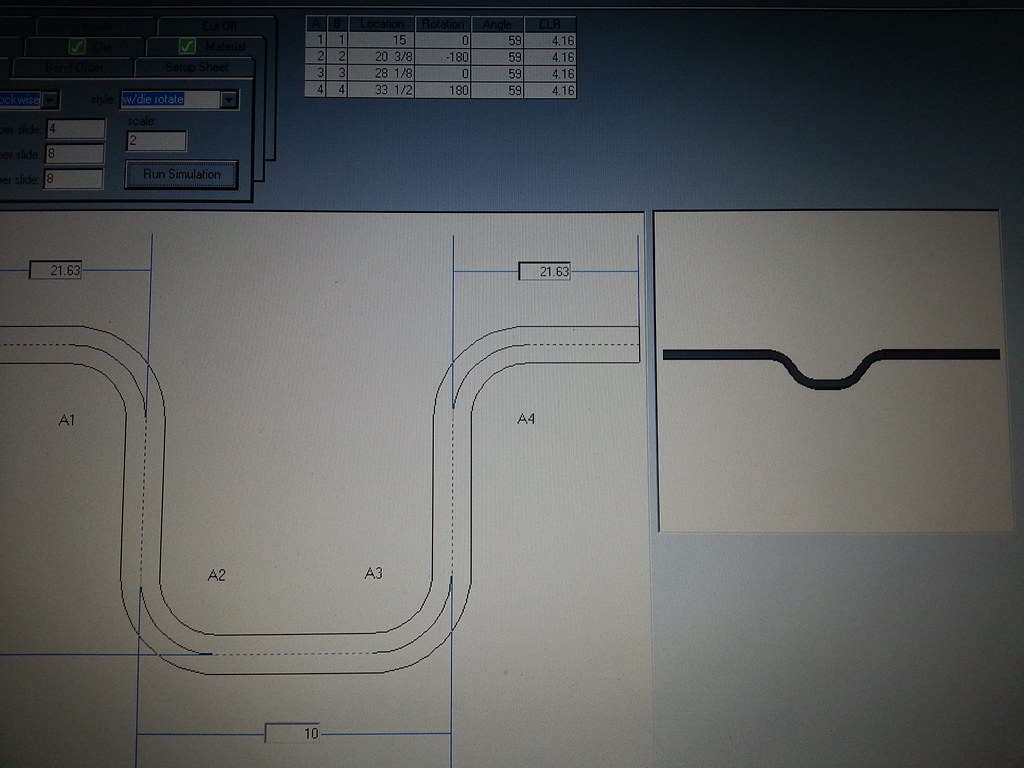

Did you figure out the square tubing bends you need?[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

Daniel,Originally posted by daniel_buck View PostI like those seat mounts, low and going over the hump like that. That's kind of how I'm thinking of running the seat mount in my TJ. Thanks for taking photos of all that stuff, I've got good reference. Keep taking photos

At the top of the hump, it looks like you've spliced two tubes together. From what I read, for rollcage stuff putting a smaller diameter 'inner sleeve' in the splice points is common. What about something like this, for the seat mounts? Do you do bother using sleeves for the smaller tubing?

Did you figure out the square tubing bends you need?

Yes, if you have to join two tube sections you have to sleeve it. A sleeve adds strength and makes aligning the two pieces easier. Normally the sleeve length is three to four times the tube diameter. In our case we are trying to use all of the tube we have, scraps and all so there will be splices in several areas like the seat mounts. The main hoops and tie-ins are not spliced. I've seen plenty of cages done this way but I don't like it. As for pictures, I take visa and mastercard. [CENTER][COLOR=#ff0000]Resistance Off Road

[CENTER][COLOR=#ff0000]Resistance Off Road

[/COLOR]Join the Resistance...

http://www.resistanceoffroad.us[/CENTER]

Comment

-

Mocking up the front fenders

20141002_175127 by MJR RAT, on Flickr

20141002_175127 by MJR RAT, on Flickr

20141002_175150 by MJR RAT, on Flickr

20141002_175150 by MJR RAT, on Flickr

20141002_175207 by MJR RAT, on Flickr

20141002_175207 by MJR RAT, on Flickr

20141002_175641 by MJR RAT, on Flickr

20141002_175641 by MJR RAT, on Flickr

Hope to have this business done this weekend. Then take the cage out and weld it, remove the tub and finish the welding on it and send it off to the blaster.[CENTER][COLOR=#ff0000]Resistance Off Road

[/COLOR]Join the Resistance...

http://www.resistanceoffroad.us[/CENTER]

Comment

Comment