Couple more items checked off the list.

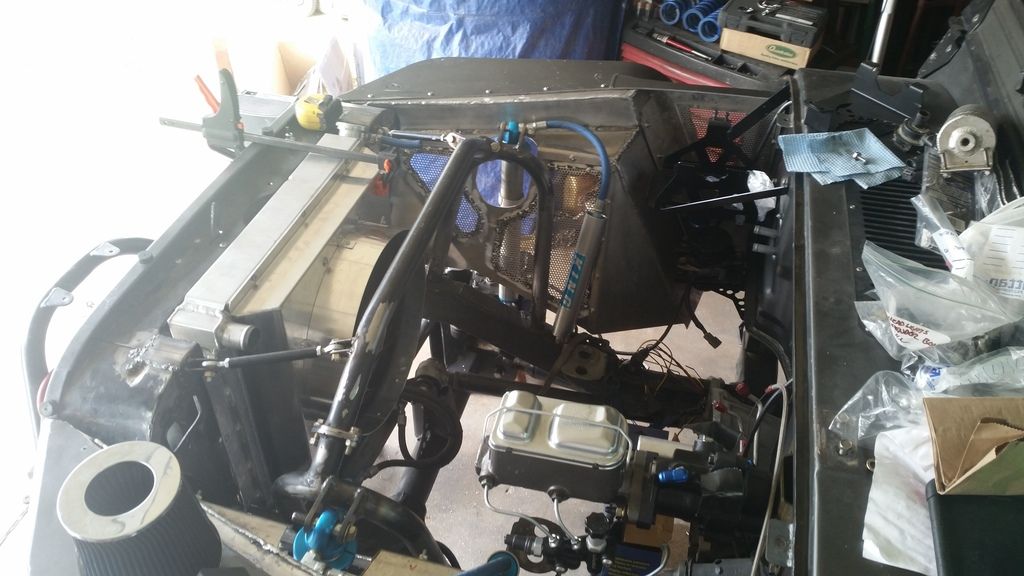

Removed the weak grill struts and replaced them with these turnbuckles I got from a GoKart site.

Attached them to the shock hoop brace. So much more support.

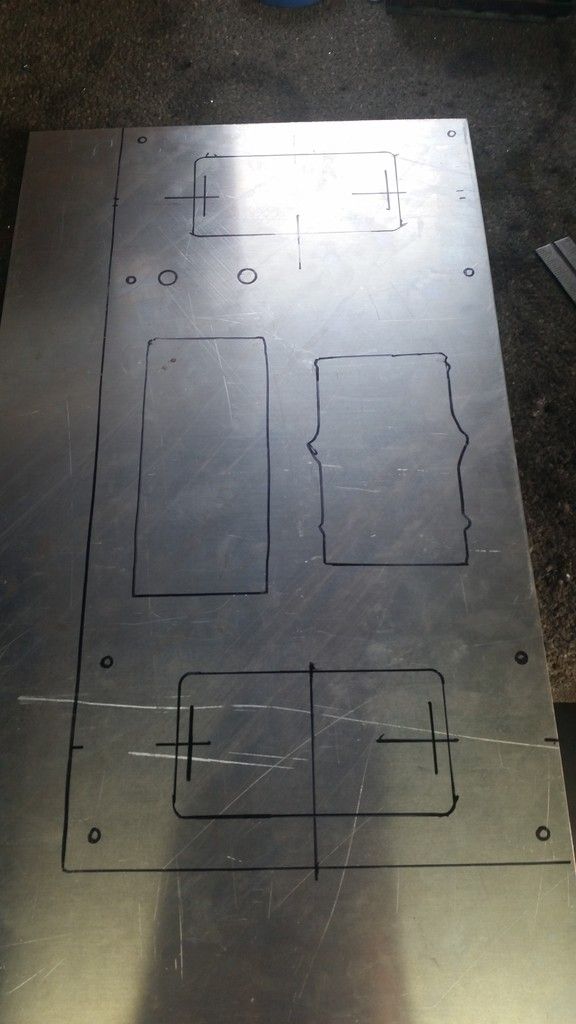

I have had nothing but problems with these Gen Wrong aluminum tube fenders. This is one of the weak points.

Hence one of the reasons I'm making these. The front is rock solid now. One down one to go.

Had to do a little more bending to match the radius of the CJ grill. Slow process.

That wheel well kicked my ass so I cleaned up early and played around with some hydrographics.

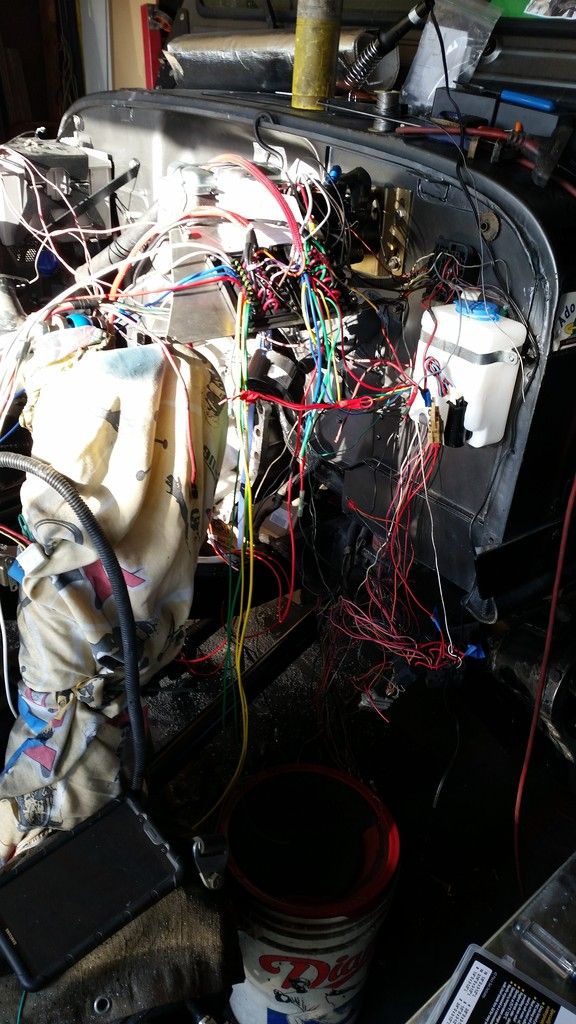

Intake hat unfinished.

Primer and basecoat

This was my first attempt at this and I'm pretty happy with the results.

Removed the weak grill struts and replaced them with these turnbuckles I got from a GoKart site.

Attached them to the shock hoop brace. So much more support.

I have had nothing but problems with these Gen Wrong aluminum tube fenders. This is one of the weak points.

Hence one of the reasons I'm making these. The front is rock solid now. One down one to go.

Had to do a little more bending to match the radius of the CJ grill. Slow process.

That wheel well kicked my ass so I cleaned up early and played around with some hydrographics.

Intake hat unfinished.

Primer and basecoat

This was my first attempt at this and I'm pretty happy with the results.

Another project for another time. Plus that wouldn't actually help with what I'm doing and strengthen the weak points on these fenders. What the inner well will do is help stop the fender from buckling when I lay it on a rock. The red arrow points to where I'm talking about. That fender has been bent twice from just laying on a rock at that point.

Another project for another time. Plus that wouldn't actually help with what I'm doing and strengthen the weak points on these fenders. What the inner well will do is help stop the fender from buckling when I lay it on a rock. The red arrow points to where I'm talking about. That fender has been bent twice from just laying on a rock at that point.

Comment