That is real sweet, Art. (Nice Job)

Announcement

Collapse

No announcement yet.

lil bit of tinkering

Collapse

Forum Thread First Post

Collapse

X

-

Well today went from wood tinkering to steel tinkering.

First made wife's day, hung the new door she has been wanting for a while.

Planed and cut it to size last week, did a bit of fiddeling with it today and it fits like a glove.

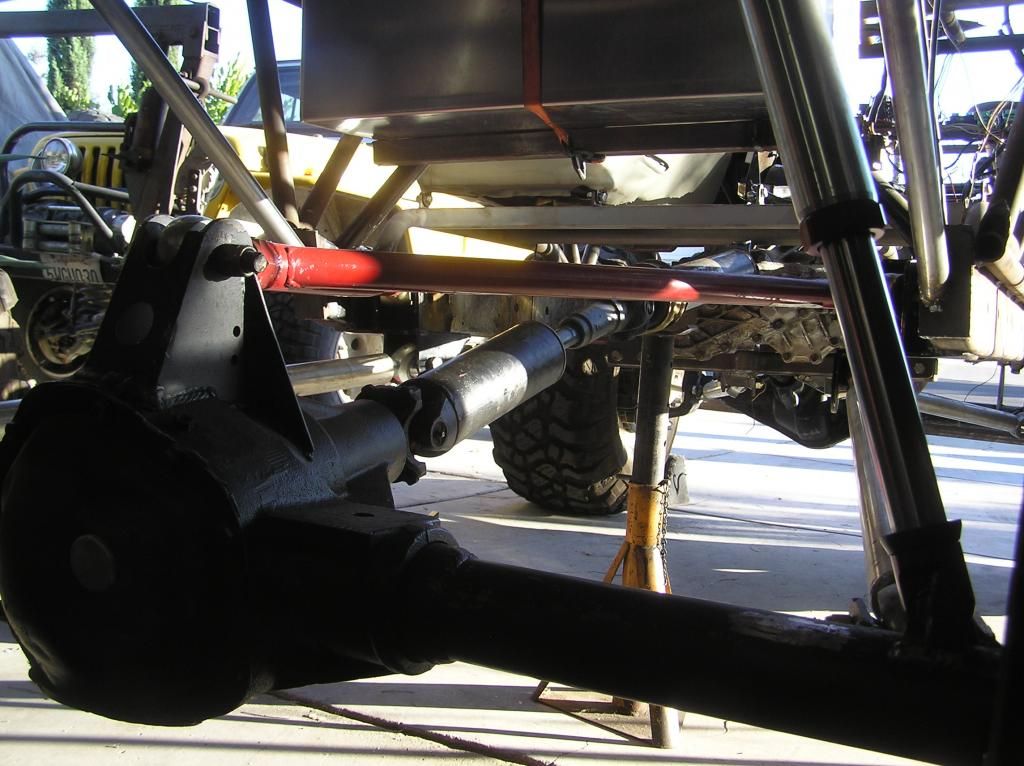

Then rolled my buggy outside and started playing with some ideas for a driveshaft.

Seems to me this will work, will allow a crossmember between the lower control arms and not restrict rear axle travel.

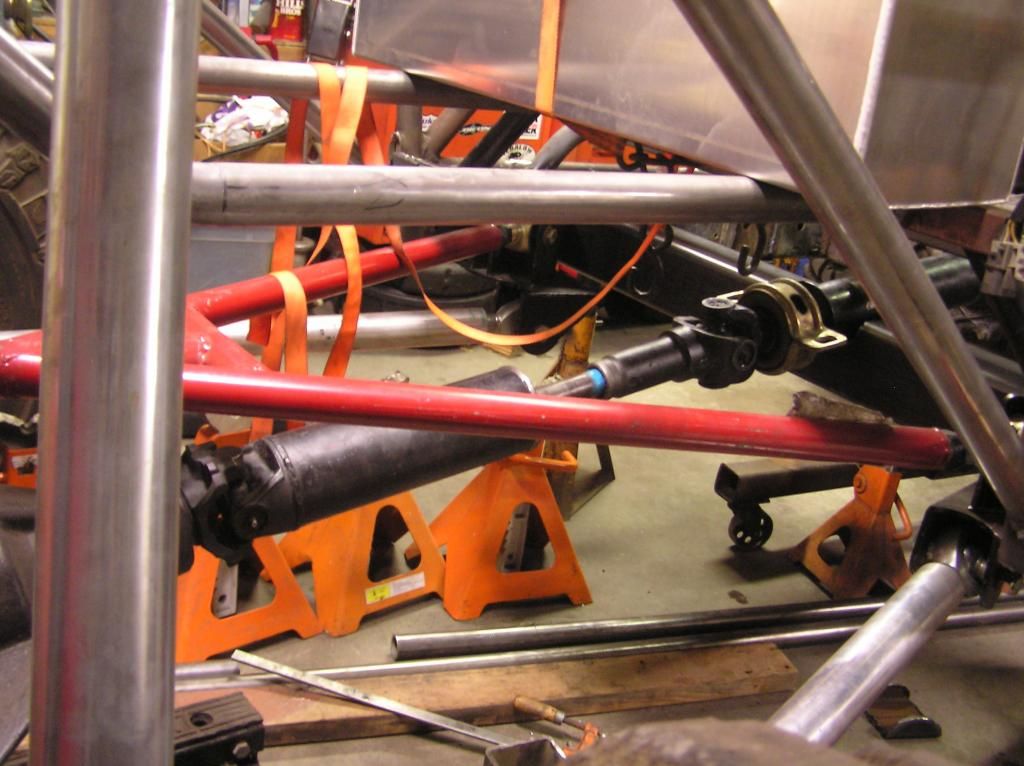

Going to add a bit of tube to the rear cage also kinda like this from both sides

Then get some more tube and bend it so the rear has a bottom, kinda like this

Here is the rough bodywork on Tinkertoy's hood, it is somewhat back to it's original shape

Comment

-

Neither can I, I'll just keep pecking away at it and eventually it will be done.Originally posted by curtis View PostGreat job on the door(impressing). Can't wait to see how the buggy works.

By the way Curtis if you want a Hammer beater that has actually a fair amount of nice stuff in it, check this one out

http://inlandempire.craigslist.org/cto/3357426944.html Coilovers and stickies what more could you possibly want for that amount of money.

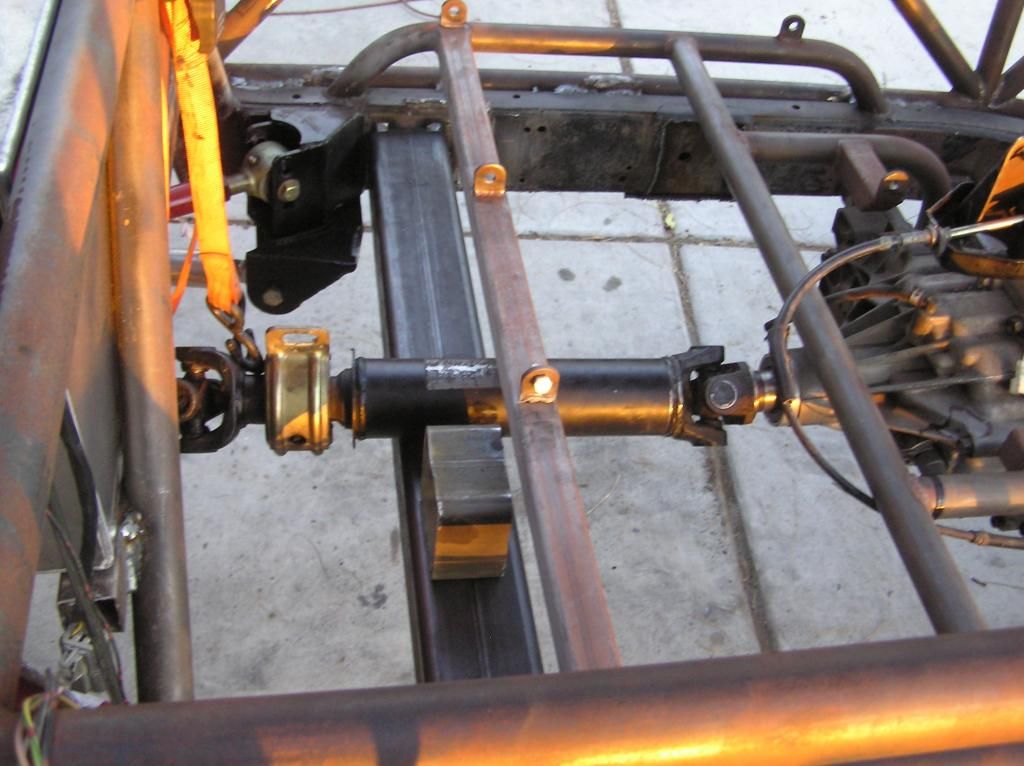

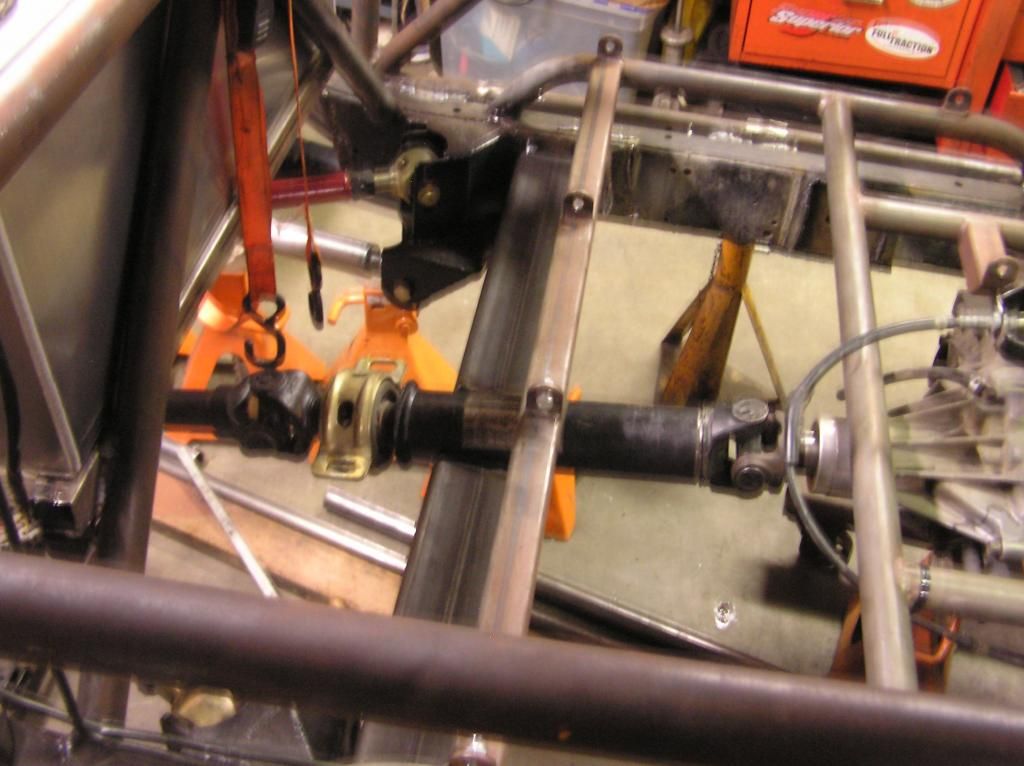

Anyway back to the scheduled program, got the crossmember tacked in now it needs some notching and French love so the primary drive shaft kind of runs through it, with a bit of work I should be able to get decent driveline angles, the thing is also [lenty stout to gusset the frame side control arm mounts too. Rear tube work is pretty much done, I am happy with it. Bottom of the frame is 24" of the ground and I am pretty happy with how it sits now and where the air shock travel is at.

Comment

-

-

nice! And that door is nice too [COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

Comment