You're gonna have to start building rocks big enough for that thing to play on.

Announcement

Collapse

No announcement yet.

lil bit of tinkering

Collapse

Forum Thread First Post

Collapse

X

-

Figured out what I am going to do for upper frame mounts in the front. Going to use a piece 3x3" 1/2" thick piece of plate that gets welded into the frame. It will have a nut welded behind it and also will be tapped all the way through that should give me plenty of thread engagement and a square piece to built the rest of the mount off. It also allows me to tuck the arms as close as possible to the frame, but still give them enough clearance to move freely through the whole range of travel.

Comment

-

Sounds like a good enough reason to me. Anti-round-out was one reason for me. Rigidity was also a factor for my frame side bracketry. Kinda funny that I actually considered skipping the clevis tabs on my back-half to save weight (I used 5/8"), but I say if you have good reason, some well-placed plate can be good.holes = cowbell

Comment

-

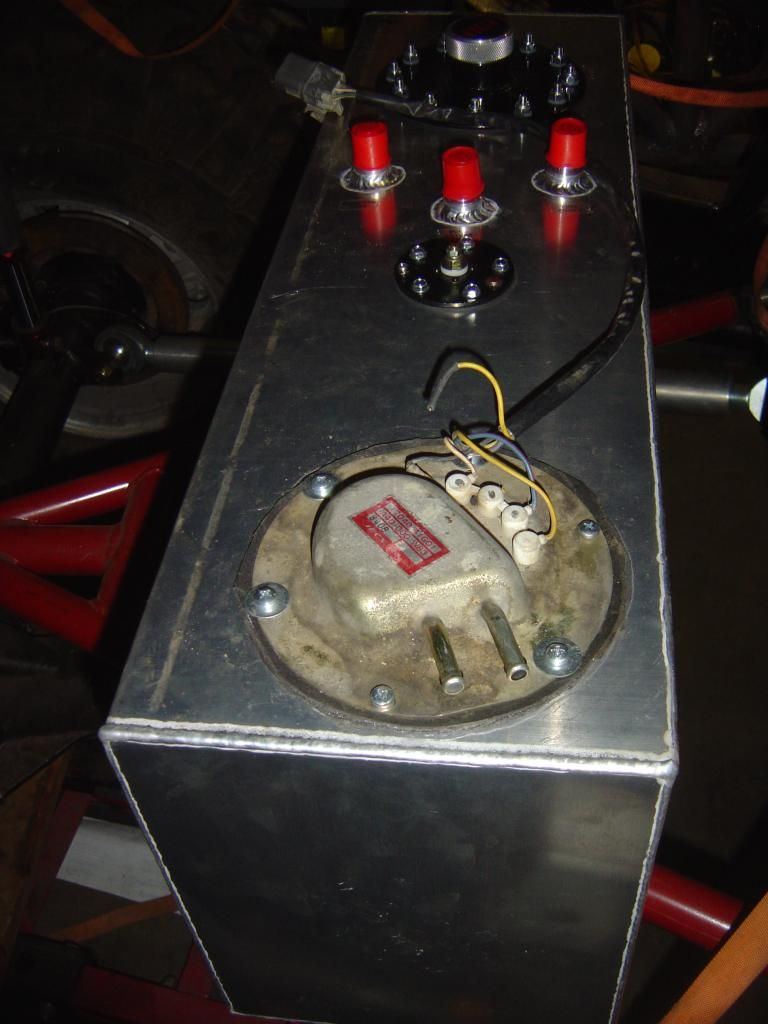

Got the fuel pump mounted in the fuel cell, only thing I don't like about is that it sits of to the side.

Will have to copy some of the KOH fuel cell pick setups. Would kinda suck to have it starve for fuel when you are having one of these having fun going almost over moments

Last edited by aw12345; 09-08-12, 07:27 PM.

Last edited by aw12345; 09-08-12, 07:27 PM.

Comment

-

Actually it flexes a bit more then my baby. The front driveshaft I was worried about but after flexing today looks like it's all good.Originally posted by Tumbleweed13 View PostThat amount of flex is impressive. How much more is that, then your big put-put? Just to play devil's advicate. Will it flex, that much with drive shafts?

The rear isn't a problem, it's going to change anyway lots of room for a driveshaft there

Comment

-

I want to narrow the bottom part of the tube frame and would like to use 1 1/2" 0.120 wall square tubing since it would make it easier to cope, attach the aluminum sheeting to the side. Anybody have any idea if there is a big difference in strength between regular 1 1/2" 0.120 wall tubing and the square tubing?

Narrowing it would make it easier for the body to slide between rocks and It doesn't really take any usable interior room away also in my opinion it would be stronger and lighter.

Comment

-

I think the strength is comparable, but the round tubing has a little higher strength to weight ratio.

FWIW, I've seen a lot more thin-walled square and rect tubing split down the seam compared with round tubing. Not that it means anything, just what I've seen by accident.holes = cowbell

Comment

-

Machining wheel spacers, made some trans cooler lines, mounted some fuse boxes.

Sorta mounted the fuel tank, next is wiring the electric fans and the trans shifter, so I can run it for awhile.

Work's been busy, so not a lot of time, nor did the hot weather help.

It's my one year project lol

Got the plasma cutter and a tube bender today

Comment

-

Comment