No this is not a race rig. This is my daily driver and fun toy!

Announcement

Collapse

No announcement yet.

Jeep build starts next Saturday Nov 23

Collapse

Forum Thread First Post

Collapse

X

-

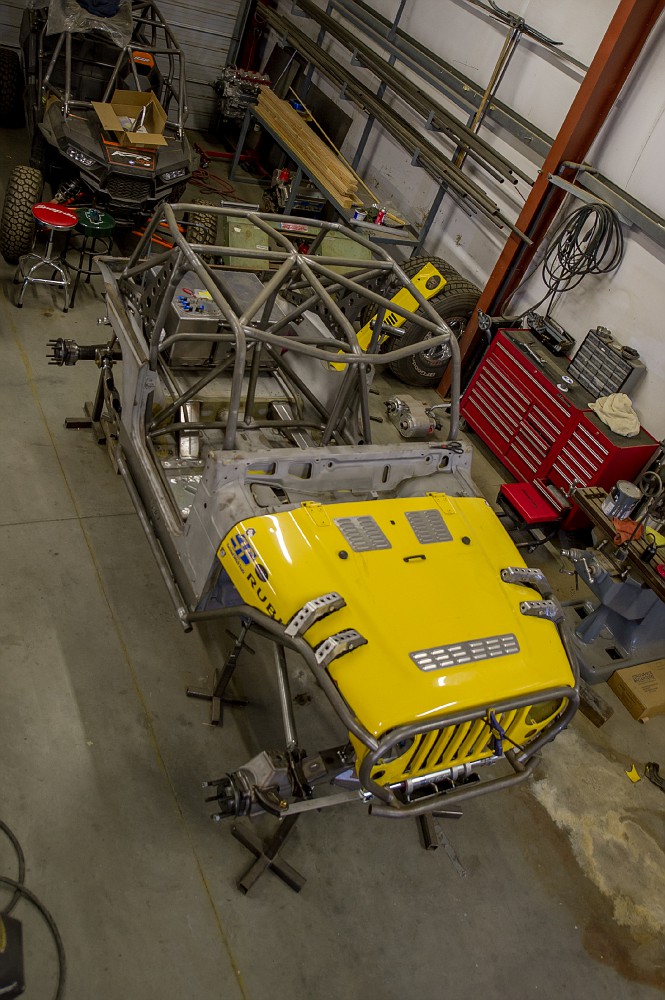

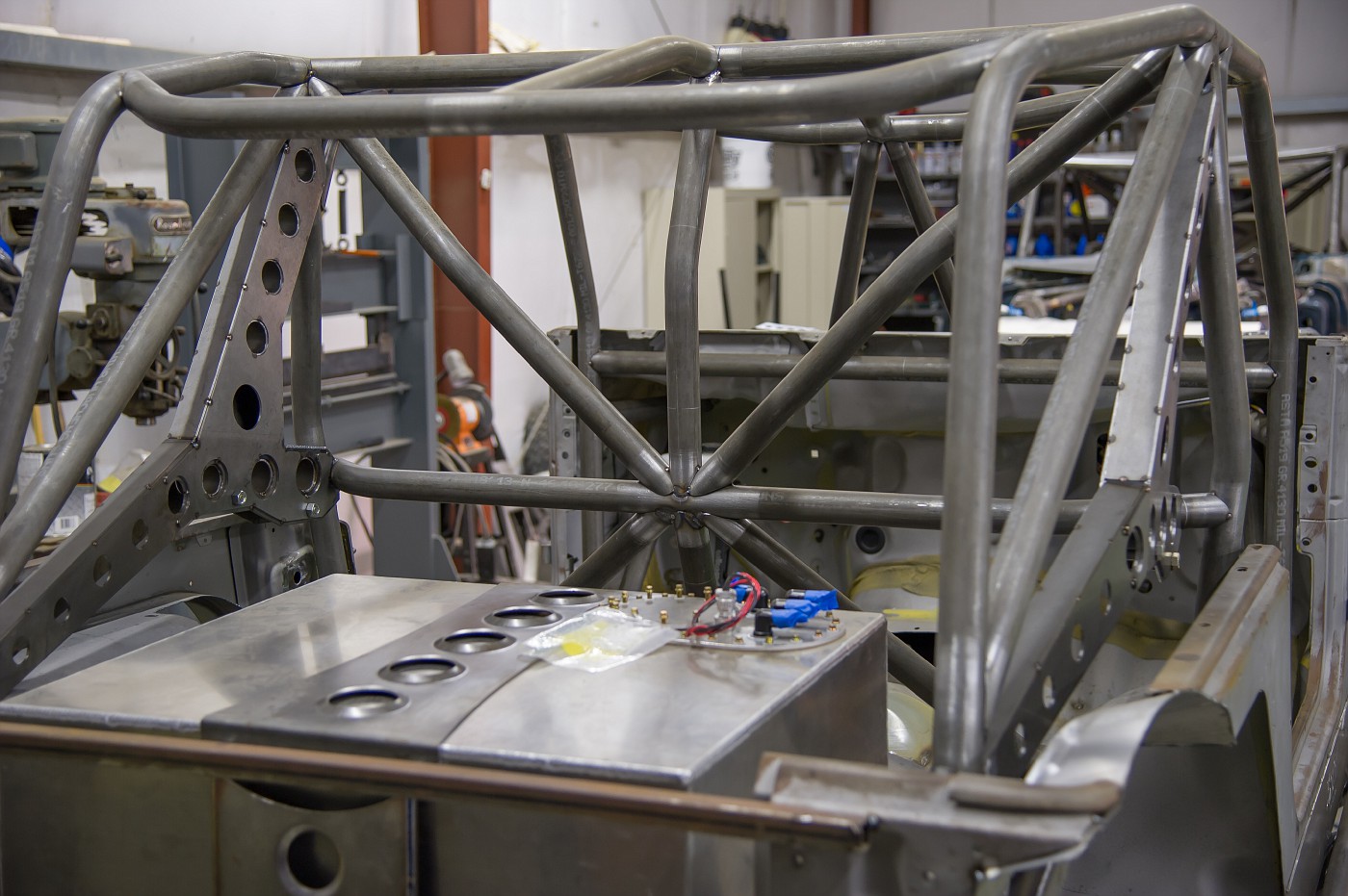

Some update pictures from today.

Working on the front fenders, front upper shock mounts, front axle truss, rear upper shock mount, rear body clearance for tires at full bump.......

The front and rear axles are at full bump and the jeep skid is sitting 23 inches off the ground but the actual ride height is 19 inches from the ground to the skid plate.

I will get some more pictures posted tomorrow.

Comment

-

I'm looking forward to seeing this one finished Don't stop taking photos!

Don't stop taking photos!

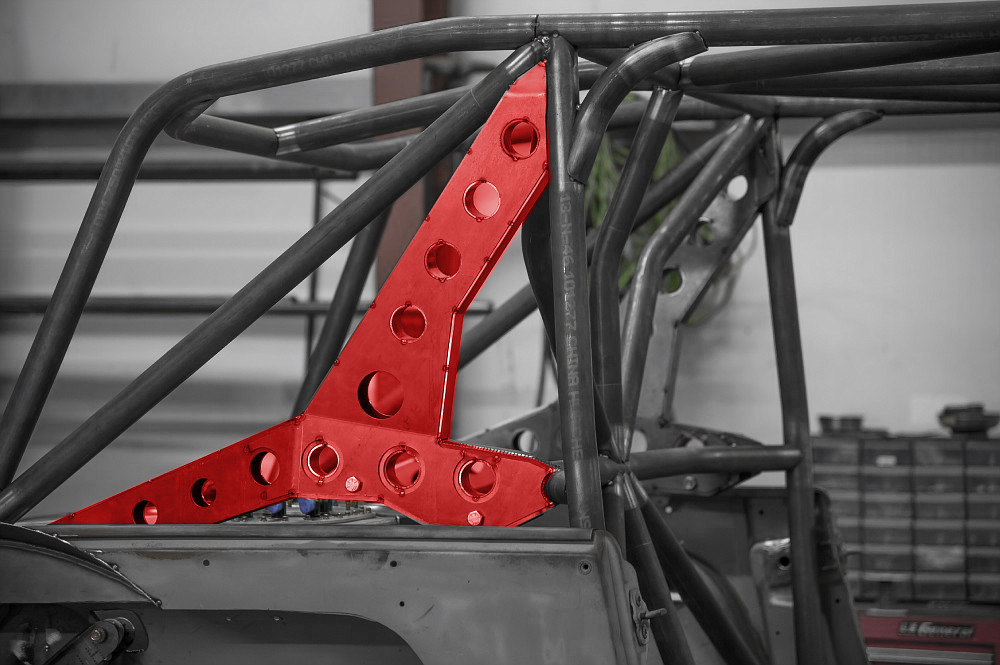

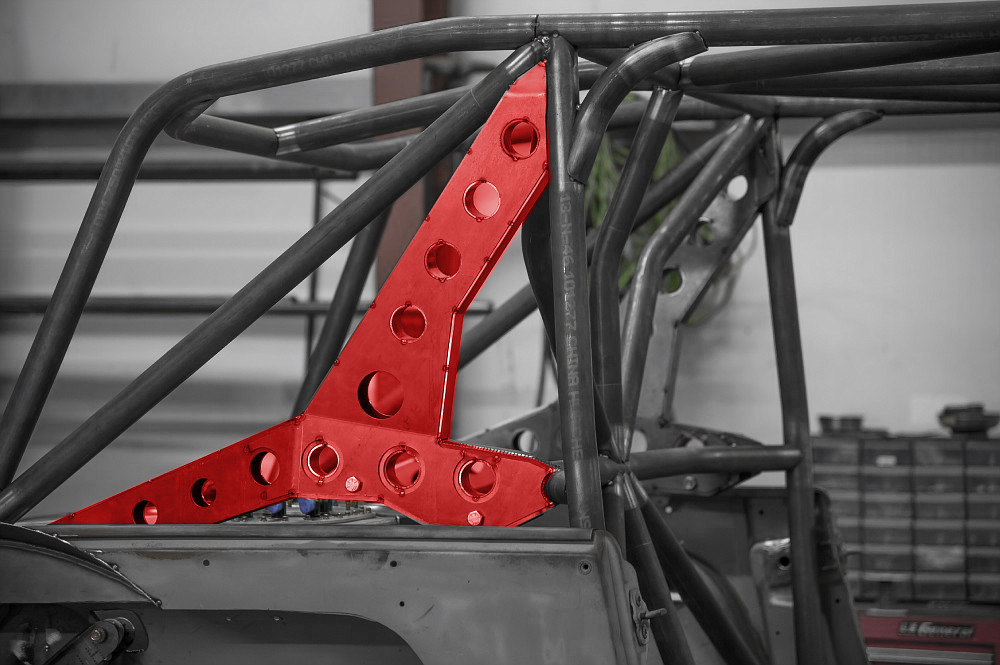

I've got a question, on areas where there are large holes drilled and then short sections of tube welded in connecting the holes, like your rear control arms, and this piece here (shock/spring mount?) it looks like the same thing is going to be done:

I've noticed that when the holes are being connected with tube, they aren't dimpled like the holes that are left open like on the axle truss, and the engine compartment brace. Is there a structural reason for not dimpling the holes that get connected? Or is this just an aesthetic decision? Or is it just easier to weld in the tubing when the holes are not dimpled?

I'm still pretty green at fabrication, I've picked up a cheap set of dimple dies because I want to start incorporating that in some future projects. Your build has been one that I've been watching for inspiration Last edited by daniel_buck; 12-21-14, 08:44 AM.[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

Last edited by daniel_buck; 12-21-14, 08:44 AM.[COLOR="#FF0000"]R[/COLOR]edneck [COLOR="#FF0000"]D[/COLOR]riveway [COLOR="#FF0000"]F[/COLOR]ab

www.DanielBuck.net - www.DNSFAIL.com - www.FurnitureByBuck.com

Comment

-

I don't know if there is a reason he does it like this. I will ask him the next time I go to his shop.

Originally posted by daniel_buck View PostI'm looking forward to seeing this one finished Don't stop taking photos!

Don't stop taking photos!

I've got a question, on areas where there are large holes drilled and then short sections of tube welded in connecting the holes, like your rear control arms, and this piece here (shock/spring mount?) it looks like the same thing is going to be done:

I've noticed that when the holes are being connected with tube, they aren't dimpled like the holes that are left open like on the axle truss, and the engine compartment brace. Is there a structural reason for not dimpling the holes that get connected? Or is this just an aesthetic decision? Or is it just easier to weld in the tubing when the holes are not dimpled?

I'm still pretty green at fabrication, I've picked up a cheap set of dimple dies because I want to start incorporating that in some future projects. Your build has been one that I've been watching for inspiration

Comment

-

I think that when you dimple, that's all you do and it leaves the part open to debris and water to get inside of the member. I think that dimpling is great to add strength to a member that wont retain debris, but these parts I think need to be closed. just my guess... :2::gun: my rifle is not illegal, it's just undocumented... :gun:

Comment

-

Build looks awesome though... I question some of what is being done because I'm not doing it. I know when I did some stuff to my Jeep a lot of people thought I was stupid or crazy, but it was my Jeep to build any way I wanted. I see this build and think... why did they do that? and then I realize, it's really a neat, one-of-a-kind custom build that most of us never really get to do and I am just glad that it's being shared on MJR so we can enjoy it. It really is a mind blowing build. So no critizizim from me, the build is super sweet!:gun: my rifle is not illegal, it's just undocumented... :gun:

Comment

-

Well said, and same goes for me! Much respect!Originally posted by Kodiak Spirit View Post.... it's really a neat, one-of-a-kind custom build that most of us never really get to do and I am just glad that it's being shared on MJR so we can enjoy it. It really is a mind blowing build. So no critizizim from me, the build is super sweet!Off road adventure photography:

TreadLightly Trainer

Wilderness First Aid (WFA)

HAM - KI6PFO

2005 Rubicon Unlimited + trailer

Comment

-

Dimpling, while often done for looks, is done to give extra strength to a flat piece. These don't need that extra strength since they're boxed and have the tubes connecting them. The other thing is, think about trying to get your torch down into that dimple to weld the tube. Wouldn't be very easy depending on the size of the hole.

I agree with everyone else. This build is more a work of art than a Jeep. Beautiful fab being shown.

RallyeX, I'm curious what your intentions are with this Jeep? A lot of it seems built more for go-fast than rocks, especially with that tire choice. Whatever you do, I'm sure this Jeep will work beautifully. Thanks for sharing it here."The Jeep...is a fitting instrument to transport the free people of a free nation with the respect to which we are entitled and the dignity that we deserve."

Comment

-

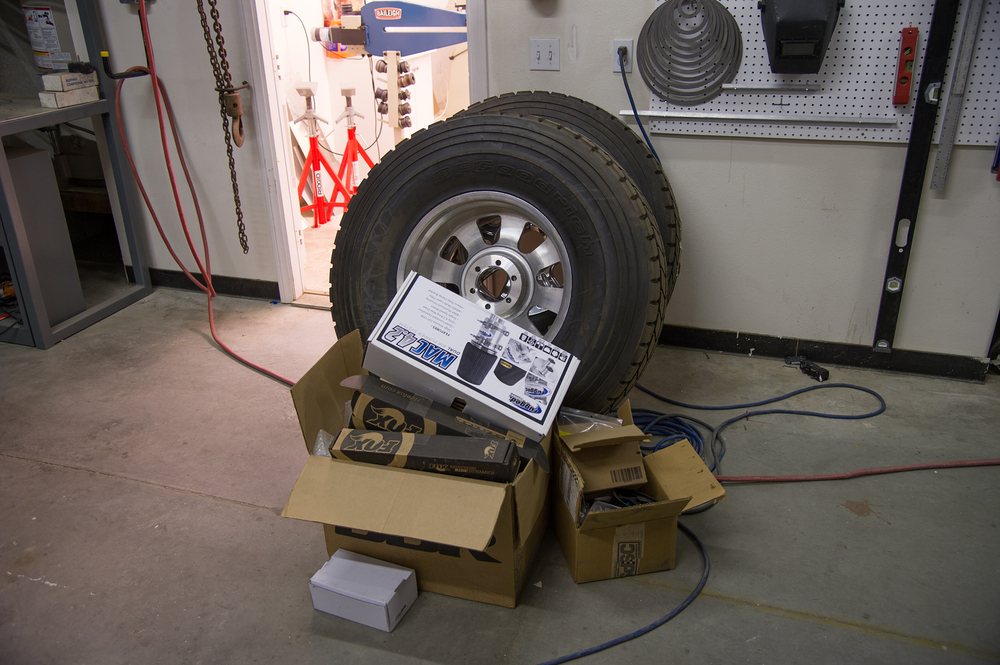

Thanks for for all the comments. The Jeep is being built for fast desert and rock crawling. I will be getting a second set of rims and running some good sticks for the rocks. We are hoping to have it 80% + done for KOH 2015. It might be in a booth in Hammertown.

Comment

Comment