I think that this is the right spot to put this thread, but it wouldn't be the first time that I was wrong. I just want to share a repetitive experience that I have had recently with my stock suspension mounts.

When I started wheeling on a regular basis and found myself starting to run some 'harder' trails (an always subjective opinion), I was cautioned about the inherent weakness of the stock mounting points for Jeep suspensions. Since at that time, I had had no problems to speak of so I really thought that the advice was overjealous. Surely, that kind of damage to the stock mounting points only comes from running the Hammers on a regular basis...Right?

Ha! Well, I can say that I have learned otherwise. Just for the record, I have been regularly offroading in Mr. Green for just about three years. In early January this year, I had a rear shock mount shear the welds after running Isham Canyon:

I probably should have reinforced both mounts, but instead I just welded the torn and broken parts back on. I added extra welds to try to prevent a repeat problem and I added welds to the undamaged side as well.

After running Hairy Crack on the last day of January, found that I had a cracked and crushed lower control arm mount on the driver's side. Notice the mis-shaped mount in this pic:

It got worse by the time I got home.

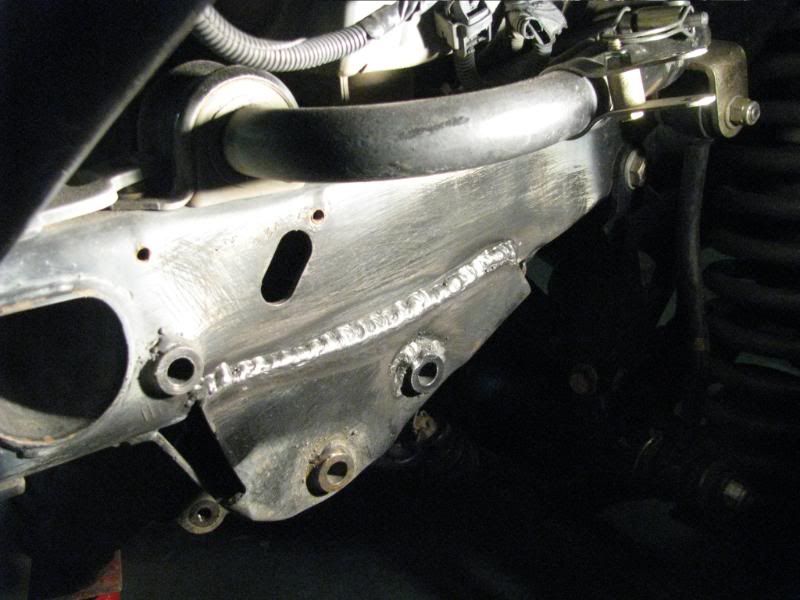

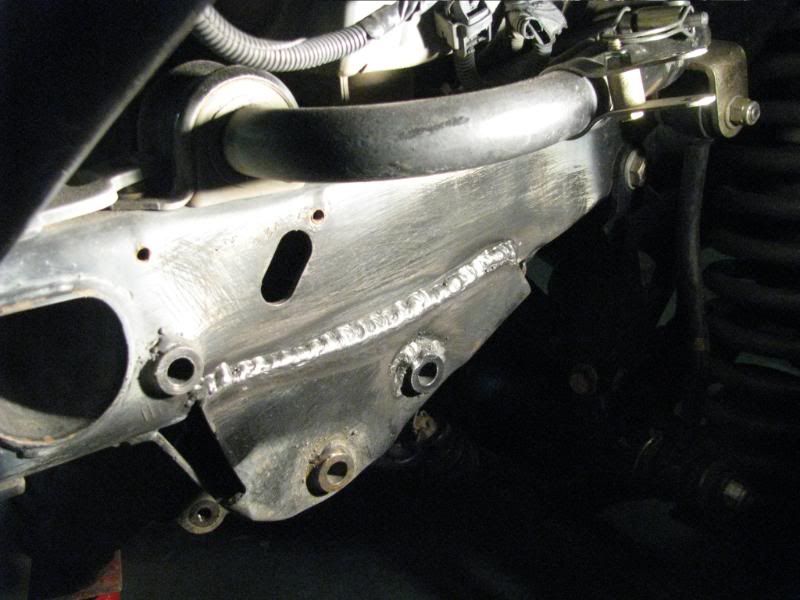

I straightened and re-welded the bent and cracked parts, and added extra welds to both of the front lower control arm mounts. I then added a 3/16" sheet metal plate to keep the mounts in position:

Okay...so now I'm becoming a believer in this stock mount problem. The real kicker (and a break that I haven't heard about before) is that after the Martinez Canyon trail in Arizona, I heard a popping noise coming from the steering, especially when I turned the tires to the passenger side. I ran Bullfrog trail last weekend and it got worse. After some assistance from my wife, I found the problem. The bracket that the steering gear is bolted to was shearing from the frame! Check out these pics, judging by the rust, this has been a problem getting worse for a while:

So tonight, I pulled the steering gear and re-attached the mounting bracket with a pretty heavy-duty weld. In the process, I found that one of the mounting bolt holes was also cracked:

After fully re-welding (using a heavy-duty weld) all four of the contact points for the bracket, I finally felt comfortable putting everthing back together:

So, a long story to get to this point... check your suspension mounts after every adventure! It's more important than you may think.

I will from now on. Just my opinion...

When I started wheeling on a regular basis and found myself starting to run some 'harder' trails (an always subjective opinion), I was cautioned about the inherent weakness of the stock mounting points for Jeep suspensions. Since at that time, I had had no problems to speak of so I really thought that the advice was overjealous. Surely, that kind of damage to the stock mounting points only comes from running the Hammers on a regular basis...Right?

Ha! Well, I can say that I have learned otherwise. Just for the record, I have been regularly offroading in Mr. Green for just about three years. In early January this year, I had a rear shock mount shear the welds after running Isham Canyon:

I probably should have reinforced both mounts, but instead I just welded the torn and broken parts back on. I added extra welds to try to prevent a repeat problem and I added welds to the undamaged side as well.

After running Hairy Crack on the last day of January, found that I had a cracked and crushed lower control arm mount on the driver's side. Notice the mis-shaped mount in this pic:

It got worse by the time I got home.

I straightened and re-welded the bent and cracked parts, and added extra welds to both of the front lower control arm mounts. I then added a 3/16" sheet metal plate to keep the mounts in position:

Okay...so now I'm becoming a believer in this stock mount problem. The real kicker (and a break that I haven't heard about before) is that after the Martinez Canyon trail in Arizona, I heard a popping noise coming from the steering, especially when I turned the tires to the passenger side. I ran Bullfrog trail last weekend and it got worse. After some assistance from my wife, I found the problem. The bracket that the steering gear is bolted to was shearing from the frame! Check out these pics, judging by the rust, this has been a problem getting worse for a while:

So tonight, I pulled the steering gear and re-attached the mounting bracket with a pretty heavy-duty weld. In the process, I found that one of the mounting bolt holes was also cracked:

After fully re-welding (using a heavy-duty weld) all four of the contact points for the bracket, I finally felt comfortable putting everthing back together:

So, a long story to get to this point... check your suspension mounts after every adventure! It's more important than you may think.

I will from now on. Just my opinion...

Comment