Originally posted by WAM

View Post

Announcement

Collapse

No announcement yet.

Intermittent no-start

Collapse

Forum Thread First Post

Collapse

X

-

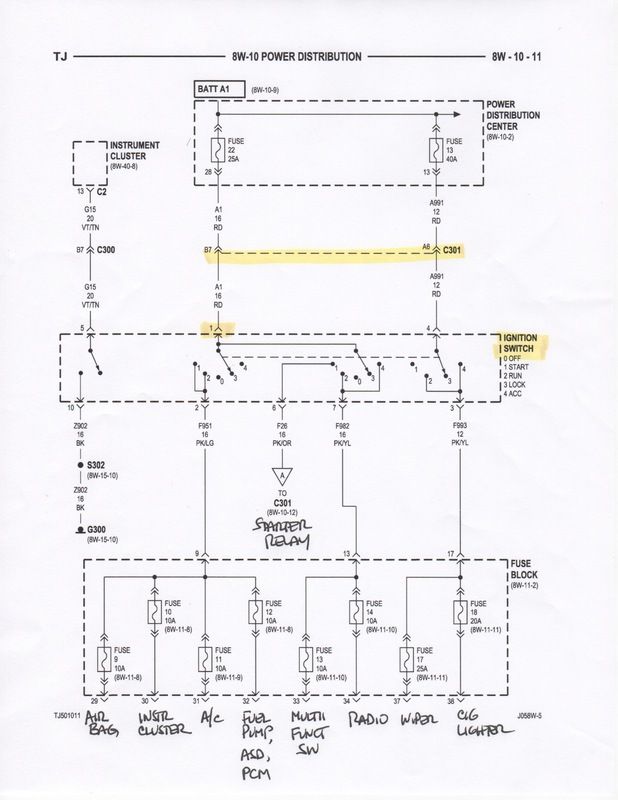

I only found two connectors where the circuits which power the ignition switch, instrument panel and starter are found in the same connector. One is connector C301. It is in the left kick panel so it is unlikely to be the cause of the problem since it is far away from where you are hitting the instrument panel to get your Jeep started. The other connector is the one that connects the ignition switch to the wiring harness. If pin 1 on the ignition switch connector was not making good contact, it would explain the behavior that we're seeing. Pin 1 supplies the power to the ignition switch when you turn the key to the start position. (It also supplies power to the radio when the key is in the on or acc position but not when it is in the start position, and power to the instrument panel when the key is in the on or start position, but not when it is in the acc position).

The connector is located in the steering column so it is close enough to the place where you are hitting the instrument panel that it is likely to be the cause of the problem. Another possibility is that the ignition switch itself is faulty. In either case, before you work on the ignition switch/connector, be sure to allow time to discharge the airbag capacitor. Here's the reminder from the Field Service Manual:

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYSTEM

BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS

OR SERVICE. THIS IS THE ONLY SURE WAY

TO DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM. FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT.If you don't like the way I drive, stay out of the bushes!

KI6MLU

Comment

-

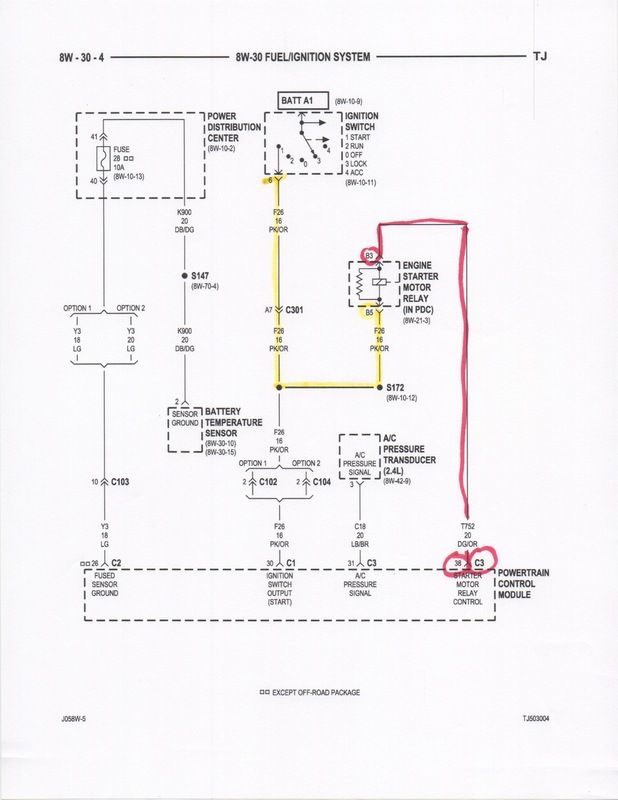

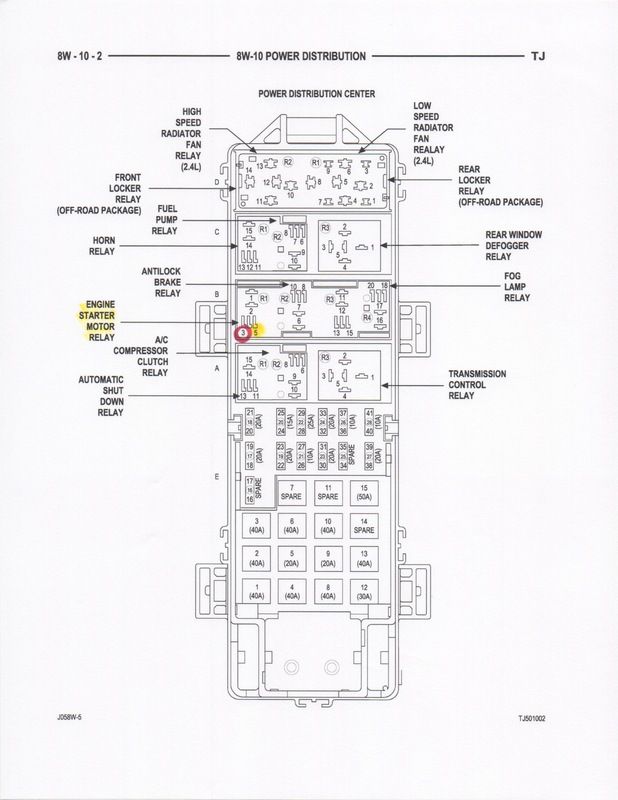

Here's the wiring diagram that caused me to suspect the ignition switch/connector.

1. Connector C301 is in the left kick panel

2. Pins 1 and 4 on the ignition switch get power from the PDC

3. When the key is inserted in the ignition switch and the doors are open, pin 5 sets off the door ajar buzzer

4. Depending on the position of the key (start, on, off, acc) pins 2, 3, 6 and 7 are hot or cold. I marked each pin to show what circuit(s) it powers.

If you don't like the way I drive, stay out of the bushes!

If you don't like the way I drive, stay out of the bushes!

KI6MLU

Comment

-

Thanks for all that. I only browsed it, but it looks interesting. I'll spend some time with it to see if it matches all my symptoms.

While I can currently fix the no-start with a rap on the dash, there have been periods in the past where the no-start was unaffected by any form of abuse I could muster.

My default position is the gauge cluster is bad because just touching it's connector instantly resolved a multi-week no-start period. Could also be that connector, but I've spent some time massaging that connection and it doesn't give a long-term fix. Still, cutting all the wires and soldering on a Mopar connector repair kit (connector with pigtail wires) would be a cheaper first step than the cluster.

BTW, I changed out the ignition switch during the multi-week no-start period with no affect.Last edited by WAM; 05-31-15, 06:19 PM.

Comment

-

So Russ, I'm wondering if I should install some test taps in various wires so I could do a quick check for presence of power during a no-start. Perhaps I could use those squeeze-connectors they use to tap into tail lites for rental trailers. Or is there an easier way to do wire harness diagnostics?

It appears I should also check radio and wiper function during a no-start, since they draw power from the starter switch through other independent branches. Does the actual engine ignition run from the same switch output as the fuel pump? I don't know what ASD is.

Comment

-

Whatever you do, do not use the clip-on wire splices. I can't emphasize this enough. They may seem harmless at first, but they actually damage the host wire under the insulation. They have to bite in to make connection. This leaves a weak spot in a soft metal on a vehicle that is prone to drivetrain and road vibration. One of the host wires will break sometime down the road - and without the courtesy of confessing which one it is because it still has a shield of insulation holding it together.

Although they were used by a well-meaning technician in the past, I have had these quick and dirty splices cause numerous day-long troubleshooting sessions.

ASD is Auto Shut Down. It's one of the relays. IIRC it stops the fuel pump and ignition if the ignition switch is on for a set period of time with no input from the CPS. It's a safety feature.God forgives, rocks don't

-sons of thunder

Comment

-

Makes sense. I guess I could just pre-mark the critical wires with tape, but I'll still have to use a straight pin or something to probe the selected wires when the Jeep goes into no-start mode. I guess I'd be looking for power on a wire coming into a connector and no power on that wire leaving the connector.

Comment

-

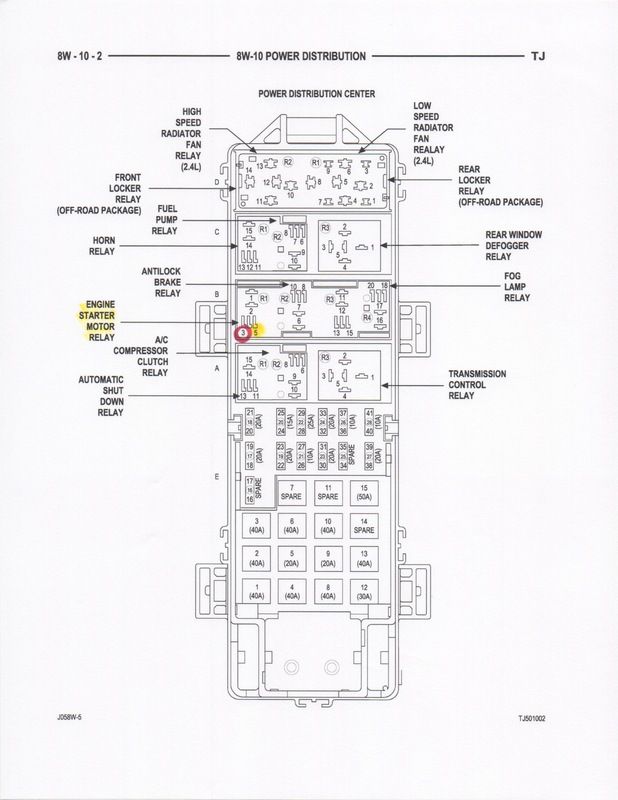

I decided my next step is to go thru the wiring diagrams and locate where all the fuse-block fuses of interest get their power. The fuses themselves make good voltage tap points, so I might be able to find differences between normal mode and no-start mode. Fortunately I have the 2005 service manual, because it seems details do change around a little from year to year. Unfortunately it's so complicated I can't get a good picture of the whole, so will work on those sections I understand. For example I don't really know what circuits out of the ignition switch actually make the car run. But I've found starter and fuel pump circuits and fuses.

Russ, I think I cleared ignition switch pin 1 because it seems the radio gets it's power from there (fuse 14) and the radio worked during today's no-start.

Comment

-

Bill,

1. Because the radio worked, we know that pins 1 and 7 on the ignition switch are OK.

2. And because you replaced the ignition switch, I believe pins 2 and 6 on the ignition switch are probably OK but we can check them anyway:

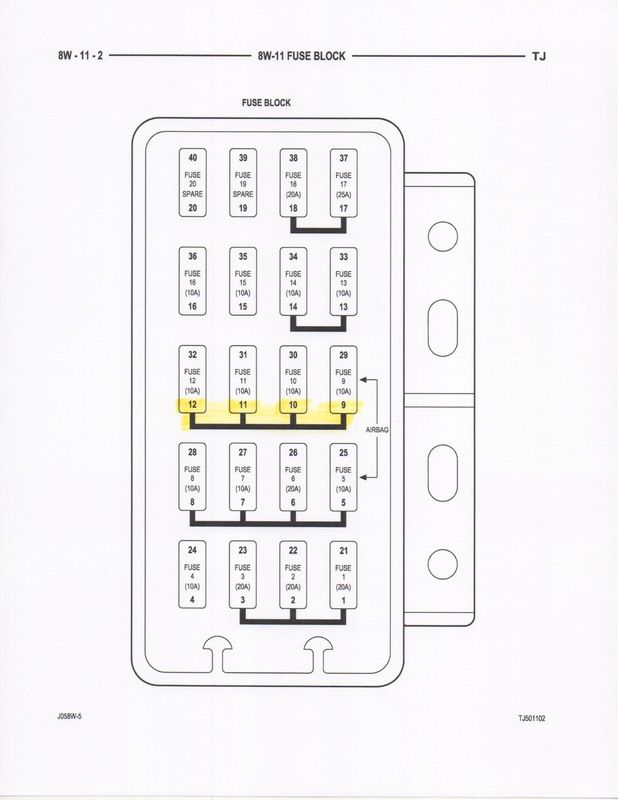

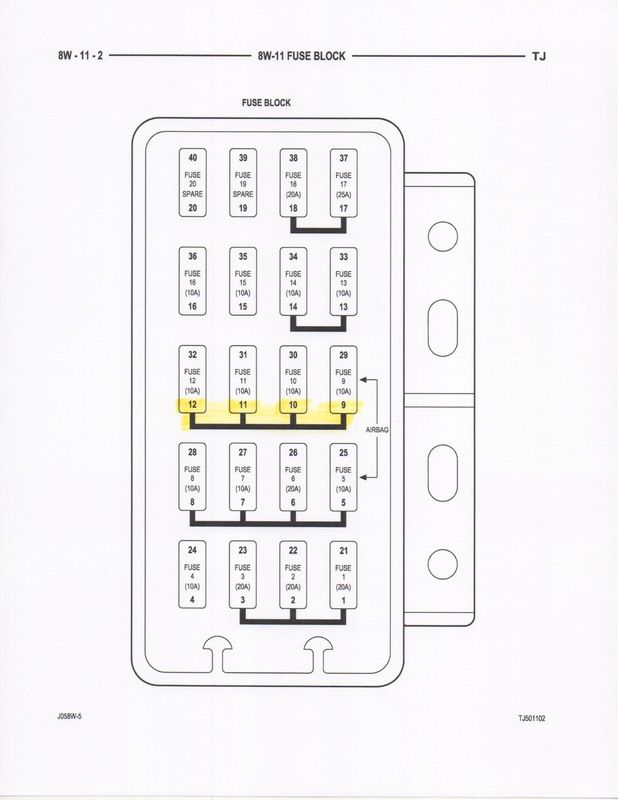

a) If pin 2 on the ignition switch is OK and the ignition key is in start, pins 9,10,11, and 12 on the fuse block should have 12 volts:

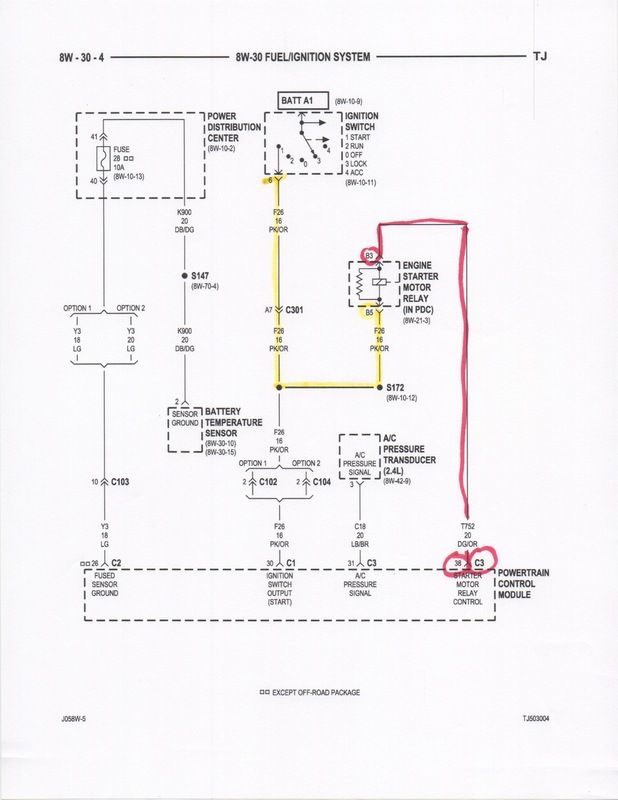

b) If pin 6 on the ignition switch is OK and the ignition key is in start, pin 5 on the engine starter motor relay should have 12 volts:

3. Assuming that these tests check out, then we can eliminate the ignition switch as a possible cause and look elsewhere for the cause of the problem.

4. A possible cause is the T752 circuit which I've highlighted in [COLOR="#FF0000"]red[/COLOR] in the two figures above. I believe that the T752 circuit is designed to disable the starter relay so that you don't accidentally engage the starter if the engine is already running. If that circuit is malfunctioning, it won't let you engage the starter even if the engine isn't running. Somehow, when you bang on the instrument panel, you do something that "fixes" that problem and also causes the instrument panel to start working, too. I just can't think of anything right now.

RussIf you don't like the way I drive, stay out of the bushes!

KI6MLU

Comment

-

Bill,

1. Because the radio worked, we know that pins 1 and 7 on the ignition switch are OK.

2. And because you replaced the ignition switch, I believe pins 2 and 6 on the ignition switch are probably OK but we can check them anyway:

a) If pin 2 on the ignition switch is OK and the ignition key is in start, pins 9,10,11, and 12 on the fuse block should have 12 volts:

b) If pin 6 on the ignition switch is OK and the ignition key is in start, pin 5 on the engine starter motor relay should have 12 volts:

3. Assuming that these tests check out, then we can eliminate the ignition switch as a possible cause and look elsewhere for the cause of the problem.

4. A possible cause is the T752 circuit which I've highlighted in [COLOR="#FF0000"]red[/COLOR] in the two figures above. I believe that the T752 circuit is designed to disable the starter relay so that you don't accidentally engage the starter if the engine is already running. If that circuit is malfunctioning, it won't let you engage the starter even if the engine isn't running. Somehow, when you bang on the instrument panel, you do something that "fixes" that problem and also causes the instrument panel to start working, too. I just can't think of anything right now.If you don't like the way I drive, stay out of the bushes!

KI6MLU

Comment

-

Okay, I'll add T752 to my list. I could cut the wire and ground it, but I think I'll take the time to make up some short spade jumpers so I can remote-mount the relay. Then I can just run that pigtail to ground instead of the PCM.

Currently I'm populating a table of -- off / run position (working) / run position (no-start) for each of the fuse block fuses. I started that today when I found it in no-start state, but by the end of my tests I realized the dash had come to life, so I need to retest. I'll add your start-position check too. Obviously I can only do valid troubleshooting when the no-start exists.

After I get that done, I'll work up a test sequence to learn as much about the inputs to the starter relay as possible. If I remember correctly we jury rigged the starter relay circuit in the field with a paper clip and could make the engine crank. But it still wouldn't start. So I believe the ignition, starter and cluster are all on the wrong end of the problem.

I'd like to check interim points along the ignition circuit but I don't understand the power flow from the switch to the coils. Does the ignition switch tell the PCM to fire the coils? Do we know which path?

Comment

Comment