No, I don't have 220 in there yet.

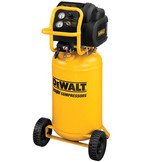

I figure if I could get one small enough to fit under the shelf of my work bench, that would be great, it would be out of the way. I'll look around.

I figure if I could get one small enough to fit under the shelf of my work bench, that would be great, it would be out of the way. I'll look around.

Comment