I usually don't get around to posting in the Fabrication section of MJR since I really don't have time to do much work, nor do I have a high caliber of skill to build a custom jeep. Now that my 3 year old son has started pre school, and my one year old naps regularly, I have found time to embark on a project.

After running the Dusy this past August with my 3 year old son, I came to a realization that I will need a jeep trailer to get the entire family of 4 out on long jeep trips (Like the Rubicon, Dusy...etc) with all our camping gear we have. I have so much money invested in my TJ, I can't see selling it to build up a JK. So I am attempting to build a Jeep Trailer from scratch.

I have searched local listing for military jeep trailers and find with a little time, effort, and about the same amount of money for an old beat up trailer I could build my own.

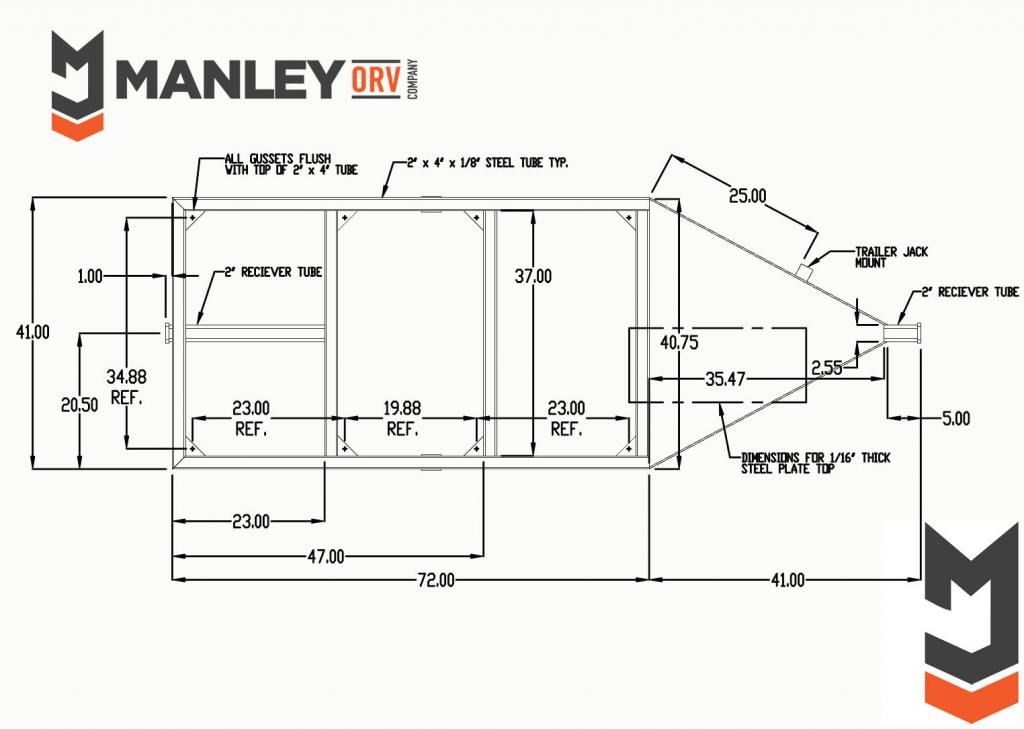

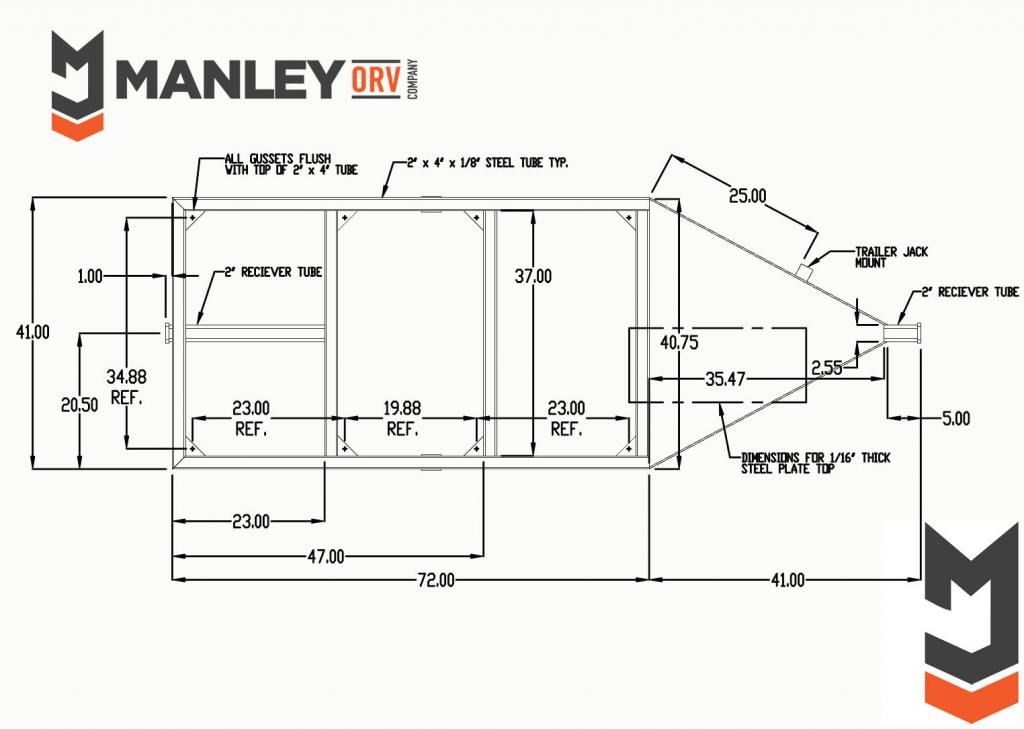

I search the internet and found a company that pretty much builds replica jeep trailers. Digging around some more I found a spec sheet and photos of what I have been pretty much building in my mind over the last month.

I plan on building the frame out of 2"x4" x 1/8" (possibly upgraded the side rail to 3/16" and cross members staying at 1/8"). The frame dimension is gonna be pretty much similar to the spec sheet.

I will be running 35" tires, with a 2200lbs rated axle

I am not sure about the bed/tub construction yet

Any suggestions from you all out there would be appreciated.

After running the Dusy this past August with my 3 year old son, I came to a realization that I will need a jeep trailer to get the entire family of 4 out on long jeep trips (Like the Rubicon, Dusy...etc) with all our camping gear we have. I have so much money invested in my TJ, I can't see selling it to build up a JK. So I am attempting to build a Jeep Trailer from scratch.

I have searched local listing for military jeep trailers and find with a little time, effort, and about the same amount of money for an old beat up trailer I could build my own.

I search the internet and found a company that pretty much builds replica jeep trailers. Digging around some more I found a spec sheet and photos of what I have been pretty much building in my mind over the last month.

I plan on building the frame out of 2"x4" x 1/8" (possibly upgraded the side rail to 3/16" and cross members staying at 1/8"). The frame dimension is gonna be pretty much similar to the spec sheet.

I will be running 35" tires, with a 2200lbs rated axle

I am not sure about the bed/tub construction yet

Any suggestions from you all out there would be appreciated.

Comment