After getting my son's roll over fixed I had time to spend on my jeep. Decided to finish the bead locks I started earlier.

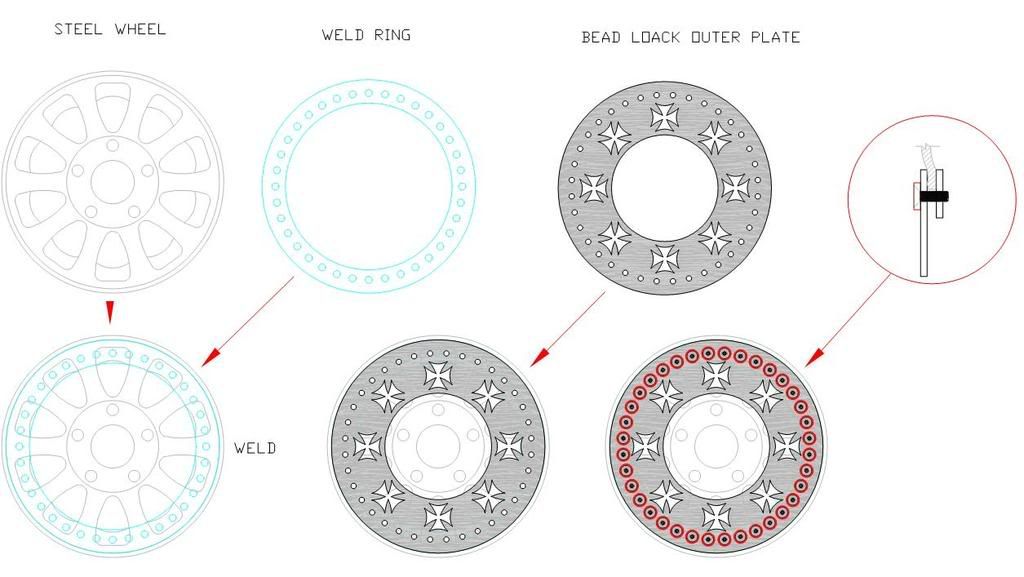

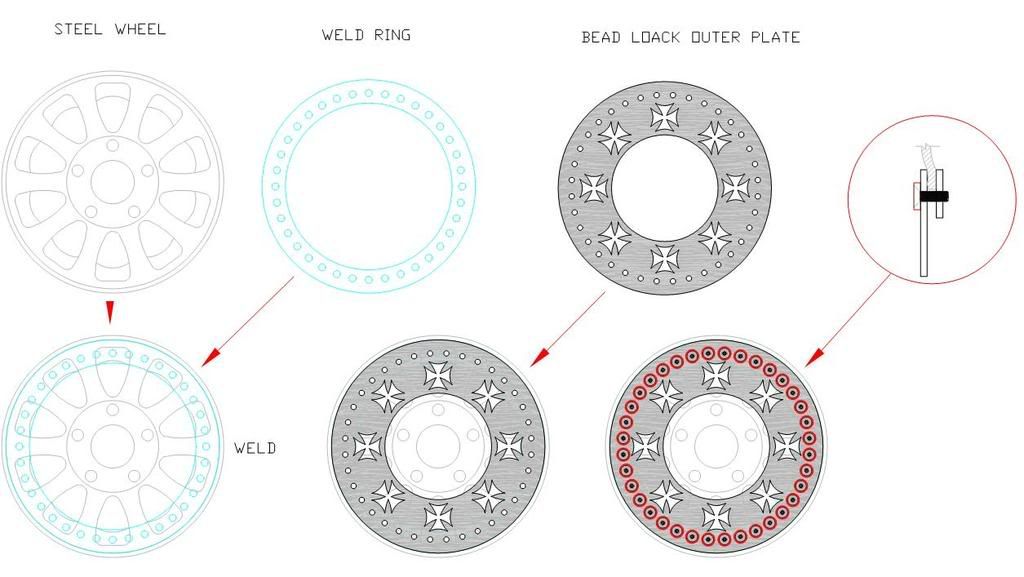

This is the concept drawing I used to design the hardware

Heres the blanks cut out ready to weld.

And here are the finished bead locks mounted and aired up.

The hardest part were the 180 bolts to tighten and torque down, it took lots of :beer::beer: to get this done. Other than that it wasn't a bad jaob to do. I tig welded the bolt rings to theels for I would have nice clean welds and no leaks. I am pretty satisfied with them. Next are custom tube fenders front/ rear and a custome cage.

This is the concept drawing I used to design the hardware

Heres the blanks cut out ready to weld.

And here are the finished bead locks mounted and aired up.

The hardest part were the 180 bolts to tighten and torque down, it took lots of :beer::beer: to get this done. Other than that it wasn't a bad jaob to do. I tig welded the bolt rings to theels for I would have nice clean welds and no leaks. I am pretty satisfied with them. Next are custom tube fenders front/ rear and a custome cage.

Comment