So after having to repair my stock skid plate after almost every run I decided it was time to build my own out of some stronger material. After much research I came up with a design. I started by getting some 1 1/2"x.120 ERW tubing and borrowing a tube bender from one of my buddies. That's when I learned that bending tubing is not that easy. After much research I decided that the Pro Tool instructions was how I was going to do my bends. This is the link to their instructions. http://www.pro-tools.com/pdf/105.pdf

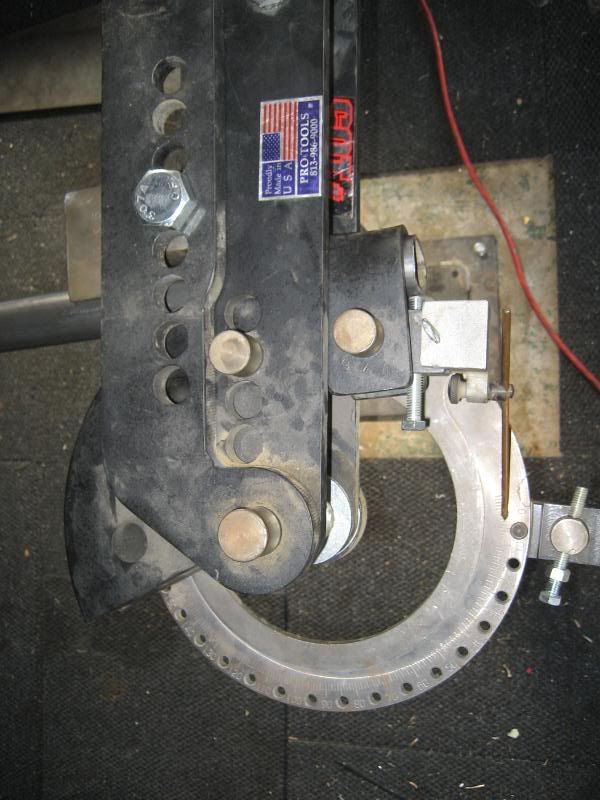

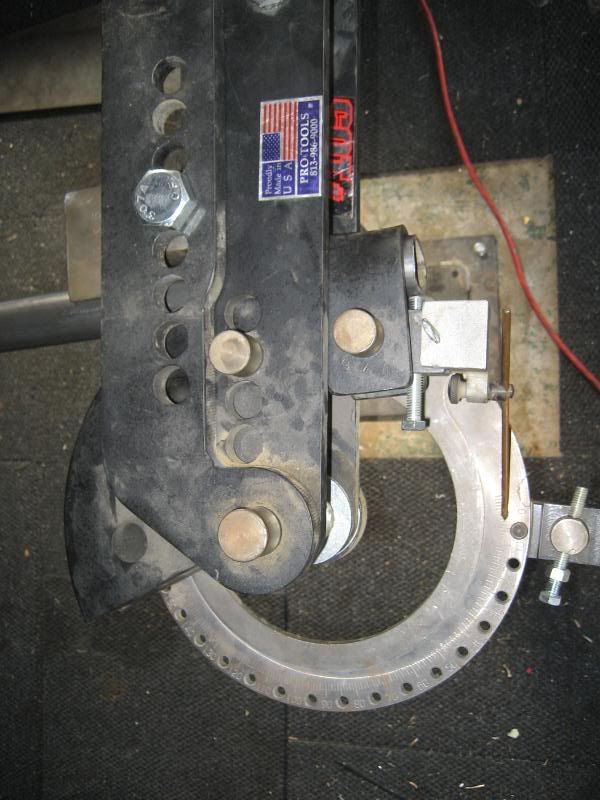

The bender I used is a Pro Tool MB 105.

I thought that .120 would be hard to bend in a manual bender but I have to say it bends really easy.

Once I finished the bends it was time to figure out the best place for the tubing. There is defiantly a limit to how far forward you can go because of the front drive shaft. Also in this picture you can see the stock skid plate that is beat to :poop:

Once I got all the clearances figured out it was time to add some strength. For this to look clean I needed to notch the tubing as clean as possible. I picked up this drill press for $40 and bought a 1 1/2" hole saw. This was quite challenging but It work out great.

After I figured out the press (long story) I was home free and things went really smooth.

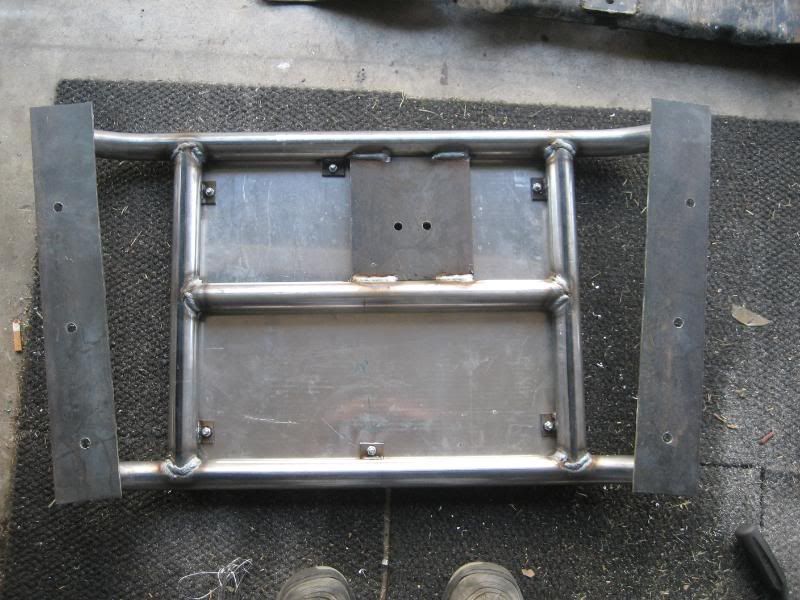

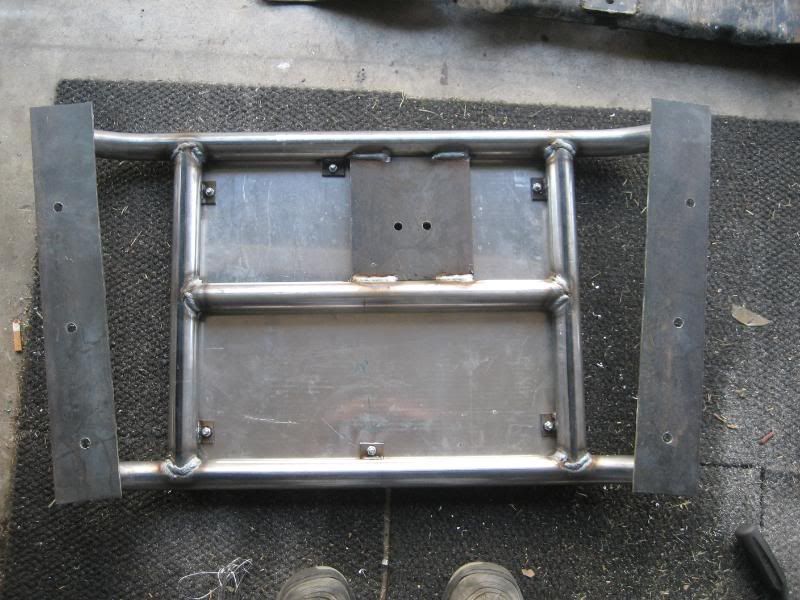

Once the cross tubing was complete it was time for the transmission mount. For this I used 1/4" steel plate.

After I got the transmission mount welded it was time for the tabs that would hold the aluminum plate on. For this I used 1 1/4"x1"x3/16" stock.

Now it was time for the aluminum. I used 1/4" for this. Again you will see the piece of :poop: stock skid. Things were starting to look good and I was happy with the results so far.

Then after about 9 hours and about $200 dollars I was done (except paint). I figured I came out ok as I still have lots of material left for future projects and I have seen similar skids for over $400.

All in all I"m very happy with the results. I would have really liked to just installed a piece of 1/4" aluminum flush with the frame but this was not possible. Now I can't wait to test it out. :smile:

The bender I used is a Pro Tool MB 105.

I thought that .120 would be hard to bend in a manual bender but I have to say it bends really easy.

Once I finished the bends it was time to figure out the best place for the tubing. There is defiantly a limit to how far forward you can go because of the front drive shaft. Also in this picture you can see the stock skid plate that is beat to :poop:

Once I got all the clearances figured out it was time to add some strength. For this to look clean I needed to notch the tubing as clean as possible. I picked up this drill press for $40 and bought a 1 1/2" hole saw. This was quite challenging but It work out great.

After I figured out the press (long story) I was home free and things went really smooth.

Once the cross tubing was complete it was time for the transmission mount. For this I used 1/4" steel plate.

After I got the transmission mount welded it was time for the tabs that would hold the aluminum plate on. For this I used 1 1/4"x1"x3/16" stock.

Now it was time for the aluminum. I used 1/4" for this. Again you will see the piece of :poop: stock skid. Things were starting to look good and I was happy with the results so far.

Then after about 9 hours and about $200 dollars I was done (except paint). I figured I came out ok as I still have lots of material left for future projects and I have seen similar skids for over $400.

All in all I"m very happy with the results. I would have really liked to just installed a piece of 1/4" aluminum flush with the frame but this was not possible. Now I can't wait to test it out. :smile:

lol.

lol.

Comment