Last fall I broke my transfer-case mount and found my motor mounts had sagged horribly. I replaced the motor mounts with the Brown dog and tried to find something for the transfer-case. I have the Nth degree skid so the mount is custom and very poorly built. Short version is five month's later, I couldn't find a suitable mount, adapting others didn't work well enough and I didn't want to make a solid mount. The mount couldn't be higher than 1 inch and shorter than 3/4 inch.

After several weeks of research I found mixable urethane. Odds are most of the people on this forum probably already know about these, the knowledge base here is very good. So here's what I found.

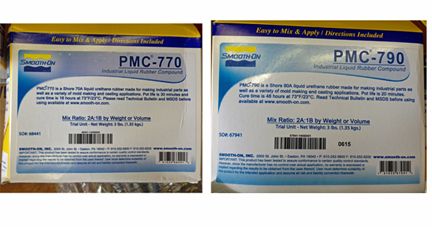

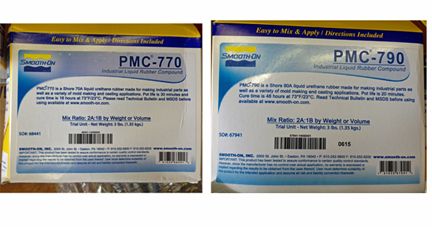

After reading forums and talking to tech people at different companies, I settled on a company named "smooth-on". Their tech line was fantastic and they have something for everyone.

First the spec's. The hardness is rated in whats called "shore". The category's give ratings that range from something softer than an eraser to harder than wood. The category I chose was "shore A". What I found was most rubber mounts are "shore A 70" and urethane mounts are around "shore A 90" So I bought one of each.

I started with the "70" and thought it was too soft so I made the mounts with "90". What I should have done was let it cure for 18 hours like the instructions said because "70" would have been perfect and "90" was harder than I wanted. Oh well.

Here's step by step.

Lower half. The plastic sleeves are to create a cavity where the lower bolts will screw in. The bolts and sleeves are sprayed with "mold release" to keep the rubber from sticking. The center hole is where the transfer-case mount bolt will recess up inside the mount. This will allow me to tighten it separately from the bottom and give a little adjust ability.

Upper half.

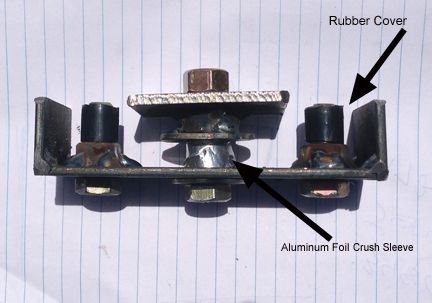

Assembled for fitting. The upper plate is sitting on a bushing made of aluminum foil. When done the upper plate has to be no higher than 1 inch. I'm using foil as a "crush sleeve". The outer bolt's will be mounted to the skid and the center bolt will recess upward and bolt to the transfer-case mount. The case will rest on the upper plate with 1/2 inch of rubber isolating the bottom.

Continued.

After several weeks of research I found mixable urethane. Odds are most of the people on this forum probably already know about these, the knowledge base here is very good. So here's what I found.

After reading forums and talking to tech people at different companies, I settled on a company named "smooth-on". Their tech line was fantastic and they have something for everyone.

First the spec's. The hardness is rated in whats called "shore". The category's give ratings that range from something softer than an eraser to harder than wood. The category I chose was "shore A". What I found was most rubber mounts are "shore A 70" and urethane mounts are around "shore A 90" So I bought one of each.

I started with the "70" and thought it was too soft so I made the mounts with "90". What I should have done was let it cure for 18 hours like the instructions said because "70" would have been perfect and "90" was harder than I wanted. Oh well.

Here's step by step.

Lower half. The plastic sleeves are to create a cavity where the lower bolts will screw in. The bolts and sleeves are sprayed with "mold release" to keep the rubber from sticking. The center hole is where the transfer-case mount bolt will recess up inside the mount. This will allow me to tighten it separately from the bottom and give a little adjust ability.

Upper half.

Assembled for fitting. The upper plate is sitting on a bushing made of aluminum foil. When done the upper plate has to be no higher than 1 inch. I'm using foil as a "crush sleeve". The outer bolt's will be mounted to the skid and the center bolt will recess upward and bolt to the transfer-case mount. The case will rest on the upper plate with 1/2 inch of rubber isolating the bottom.

Continued.

[/COLOR]

[/COLOR]

Comment